Everything posted by Peage

-

Autumn Zed pics 2022

Wow, both cars look amazing.

-

OEM boost gauge not working after Nistune install (now solved).

Might sound silly but smack the top of the dash. Mine occasionally gets stuck at the minimum position.

-

No power steering after HICAS delete

Just reporting back in on this for anyone else who has the issue - seems the resolution was very short lived. It was fine for the first small test drive but has been back to being heavy ever since. I have since replaced the rack solenoid (resistance tested the old one and it was within spec anyway) and the new solenoid did not resolve the issue. Weirdly after first doing the solenoid, immediately after start up, it was fine for a brief period. After going lock to lock a few more times for bleeding and letting it idle, it went back to very heavy again and has remained that way. I now have a power steering high pressure switch to fit. Based on the previous, I assume something is making it drop into failsafe mode and the pressure switch is the last thing to try. Fingers crossed.

-

Thoughts On Paint Colour

I don't know exactly which replica spoiler is mine but I guess it's probably that one. The fit is not great, you likely won't get it to line up with the bottom of the boot lid perfectly. I'd make your decision with that in mind.

-

Thoughts On Paint Colour

I'll put a vote in for original pearl white and either a 89 spec replica spoiler (with dodgy fitment, like mine) or one of the low laying twin Z spoilers. Personally not keen on the spoiler-less look. Original 89 spoilers are stupidly expensive, if you can even find one.

-

ADAMZX's OEM+ 2000spec Version R Replica Conversion & Rebuild Project Build Thread

Will be interesting to follow along and see all your option parts!

-

300ZX TT - A18GCK

Just an FYI on the rear seat quarter trim. Mine did this and some light heat gunning to stretch it back to shape and spray adhesive fixed it right up Although with how your build has been - I would understand if you would rather retrim or replace!

-

Smoking z32! Z32 Newbie needing help.

Likely your one of your turbos is failing. After hard acceleration and lifting off, do you see more smoke in the rear view mirror?

-

Tachometer Accuracy

My Z's tachometer has always read high when compared to either Conzult or more recently also my Racelogic, which taps into the tach line from the ECU. For example, at warm idle my tach reports a smidge over 1k, while the Racelogic/ECU reports 850. This continues all the way through the rev range. I just wondered if anyone else has found theirs is the same or better yet if there may be a fix for this?

-

Underbody and all that goes with it.

Can it be chemically stripped at all?

-

Spare Wheel Well

Isnt it a bit too shallow for much anyway? Plus it needs to be there for the boot floor so have its shape. If it was deeper, one of those spare wheel sub installs would be good - it's definitely not though.

-

No power steering after HICAS delete

Just to report back in on this - in my case the pump replacement seems to have resolved the issue.

-

Mods Declared Insurance Company Recommendations?

My mods are covered pretty well in my premium journal on here called Black UK Z. There's a performance spec list somewhere on the first page. Weirdly the biggest issue was the car having a period of being uninsured. Quite how you're ever supposed to fix that when most won't offer a new policy, I don't know. Level of power increase was also mentioned as an issue too. It's at 465hp. Nothing mental.

-

Mods Declared Insurance Company Recommendations?

Wish I'd seen your post about ClassicLine Andrew! Had not tried them. I was rejected by Performance Direct, GreenLight Insurance and a couple of others for a multitude of reasons. FYI - My license is clean etc so no issues there. The main barrier seemed to be the level of mods and the fact the car has not been on the road for a while. I was told upfront my Greenlight, who genuinely focus on modified cars, I won't find cover and all their companies had rejected it. Lack of recent reference of an insured performance car. Lack of immobiliser/alarm. My stated valuation. FYI for anyone who comes across this in a similar pickle, Chris Knott were able to find a policy for me but could not get me on an agreed valuation classic policy due to the mod list and other issues stated above. They were great and seemed to try the hardest of any of the firms I spoke too - who all seemed annoyed by me asking for a quote to be honest! By the point the person working on it for me at Chris Knott called me back I was ready to take anything offered though. I am 31, clean license, no claims and paid £497 for the year. For reference, the policy on my daily driver is around the same so pleased with that price... although not in the £100-200 range some manage to hit on here. As Gaz says though, many other factors at play too. I think my lesson here is to keep the car insured regardless... But I needed as much cash as possible at the time to start my business so no regrets either. ?♂️

-

Mods Declared Insurance Company Recommendations?

Looking to get my car insured again - all mods declared. Do people have recommendations? I tried performance direct but they told me they cant offer me anything instantly and it's one they would need to "put out" and come back to me. Also sent details to Greenlight insurance and am waiting on quotes. I have seen elsewhere that Adrian Flux are very expensive these days. Any info on what people pay would be helpful too. UPDATE: Performance direct have said they can't offer any cover as the insurer does not like that the car has been off the road for the last year and a half? Strange.

-

Black UK Z

Bit of a suspension update here. When the car was last on the road, the camber up front was always mismatched between left and right. I purchased the Whiteline camber bushing kit for the FUCAs but when it came to fit I realised a set was already installed! I had previously had these swapped out for what I was told were just regular polybushes at a certain garage in Doncaster. I was thinking they were expensive for bushings at the time but also had total trust in that garage at the time. I was never advised they were camber adjustable and certainly was never advised they would need adjusting after fitment. I did have an alignment done after this change but the person doing it also had no idea about the adjustable bushings and did not touch them... he was just stumped as to how the camber was off between the two sides. Now I know. One problem I had since the previous install of these bushings was horrendous noise. I complained and took the car back to the garage once but he simply packed the brackets with copper grease and sent me on my way. Suffice to say this only killed the squeaking for a few days. I found the garage did not bother to install the included grease nipples in the arms to provide proper lubrication.... Annoying. I have since redone the install properly and took the opportunity to have the arms powder coated at the same time. Most importantly, we can achieve matching camber up front now - rather than bushings installed at who knows what angles unbeknownst to me like before. Original Install: New Install with grease nipples fitted: I have also deleted the HICAS at the rear and installed Driftworks arms with polybushes and installed subframe collars at the rear... Not a fun job with the car at minimal height on jackstands. At the time of deleting the HICAS I ran into power steering problems which I will cover in this thread at some point... still waiting to confirm the fix on that. I have also installed the Tein EDFC motors on the strut tops and added a rear strut brace too. I did not thread the wire along the path shown in the pic below! Cut into the boot plastics to allow for the strut bar and cut some rubber edging to suit. Not shown here but I also drilled small 2 holes either side of the gap on the bottom lip of the plastic and zip tied the piece together tightly. These zip ties are hidden under the carpet and gives tight fitment.

-

Black UK Z

Don't think I've seen that before!

-

Black UK Z

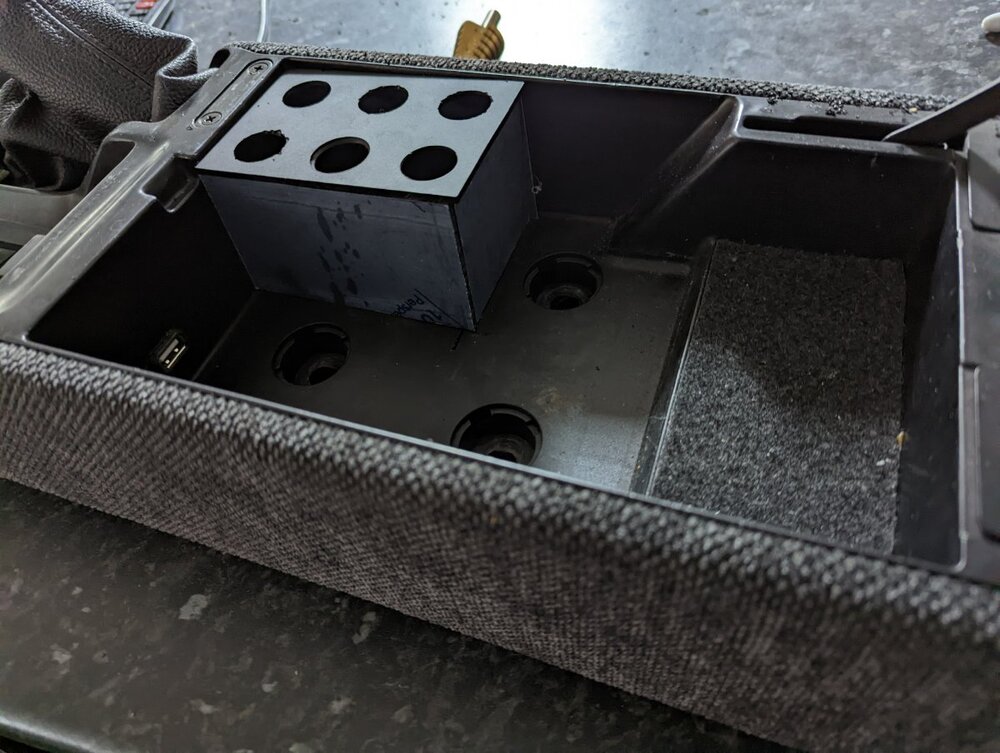

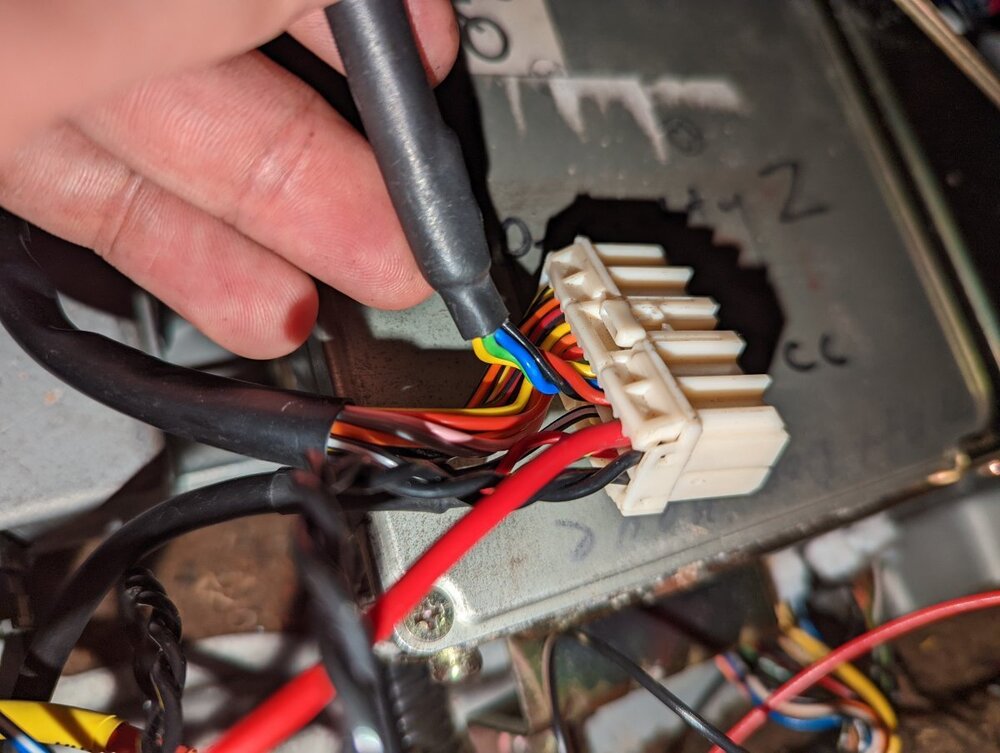

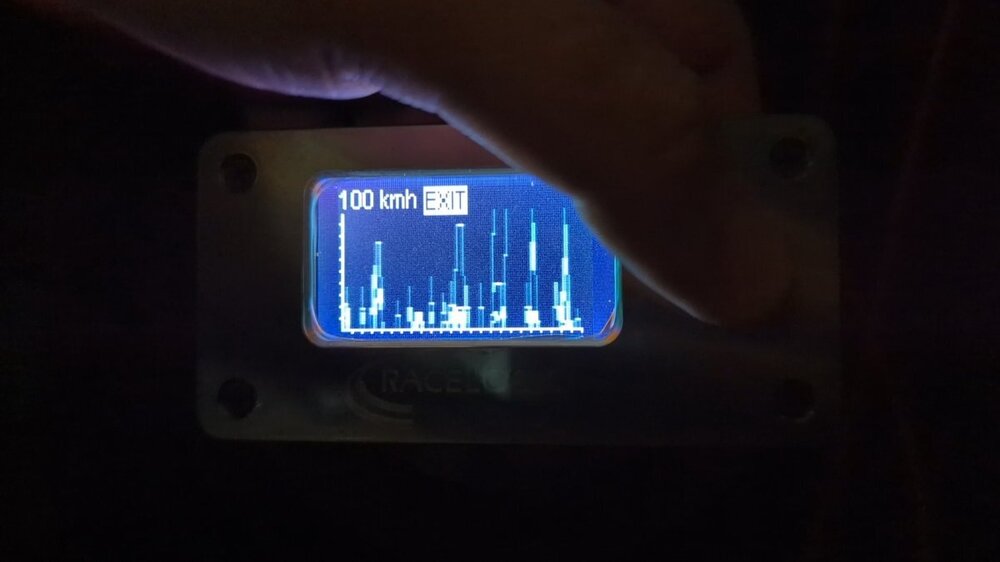

Moving on from Racelogic woes for now, something else I have been working on is adding some buttons into the centre arm rest. My Tein EDFC active suspension system accepts 2 external inputs to make instant custom adjustments to the damping settings of the car which I wanted to take advantage of. I figured, while I am adding buttons I may as well make a box for any future needs (I have some late UK spec seat heaters which someday will end up in the car that I will likely control from here) but also to move my power antenna control into this unit too. Previously I had bought a folding mirror type mirror controller and wired the power antenna to what should have been the mirror fold switch. I have now reverted that back to my standard unit. Just decided to make the box from some black perspex. A quick mock up highlighted that I needed to make account for the sloping bottom of the console: Once I was happy with the fitment, time to piece it together: Decided to wrap it in black suede like material and would be swapping out the factory console carpet for the same material too. It was only at this point that I realised it would have been ideal to match the width of the box to the cutout in the lip of the centre console, it was somewhat close by accident. Ultimately, I did not want to start again and this did not bother me too much. Made up the wiring for the buttons, with some connectors so removing the centre console in the future is straightforward. The buttons for the Tein system are over-complex because I wanted light up switches but the Tein external inputs are asking for a switched ground, so what you see there is the solution. I also labelled the buttons as I saw fit. And the final result below. Note the centre console carpet was just placed in there for now to give an idea of the final look, hence it being curled up a bit. I have also since re-cut this anyway as I was not happy with the shape. And here is a little GIF of a quick test I did in the car. You can also see the reaction of the Tein controller to movement, albeit only the rear struts were setup with the system at the time. It works based on GPS speed of the car and G forces.

-

Black UK Z

Sadly, looks as though my unit is beyond repair even with the new processor. If anyone has one of these that is surplus to requirements, please let me know. The Racelogic response is below.. I managed to start looking at this again last night. I successfully removed the old processor and soldered on the new one, and then progressed and managed to install the base code using our DOS prompted laptop (picture below to give an idea of what I'm working with). It is the only laptop in existence which runs DOS and has the code written into it. The screen is barely visible nowadays. Anyway, the item to the left of the laptop is our in-house test jig which we use in conjunction with the Traction Control PC software. This is also as old as the hills and on its last legs! So the base code is now installed, however I am no longer able to connect to the module via the test jig to the PC software in order to install the main code. It is a little gutting for me as I know how keen you are to have this module working again, but I think it is now time to cut losses with this one. They do occasionally pop up on eBay etc, so it might be worth a browse, or there are some other options out there (I think Deborah mentioned some in earlier correspondence). My current theory is that either there is underlying PCB track issues (deterioration / corrosion), or it could be the DOS code. Of which the latter will likely never be investigated further due to the resource required. I am sorry that it is not a positive outcome after you managed to source the processor, but I think we have done all that we can with this one. I did stay a bit later last night (my own time), out of curiosity trying to get it going, but I think that as a gesture of good will, and to help minimise your loss, I will only charge for the initial inspection/ repair attempt, and a single hour of labour for the installation/programming/ testing of the processor that you sourced.

-

WANTED - Racelogic Traction Control

View Advert Racelogic Traction Control After purchasing a Racelogic Traction Control that was faulty, I am desperate to source a new module/control unit. If anyone has this system for sale, I would love to take it off your hands. Advertiser Peage Date 12/07/22 Price Category Parts - Wanted

-

No power steering after HICAS delete

I have not confirmed a fix yet. I ended up buying a refreshed power steering pump but have not yet had the car down on its wheels and running again as I have been working through some other bits on the car like dropping the fuel tank, replacing fuel lines, refreshing upper control arms, etc, etc, etc. The new pump is fitted and will probably be tested in the next week or two. How did you perform the delete, was it the same as me? I deleted the HICAS solenoid along with removing the rear rack.

-

Black UK Z

They are definitely of the multicoloured variety. I actually didn't know they could be red so definitely interested to hear where you're going with it. Is red for the non-abs cars by any chance?

-

Smaller Washer Bottle for UK Spec?

Just wanted to say thanks @AndrewG. Took your idea for mine and implemented this a little while ago...

-

Black UK Z

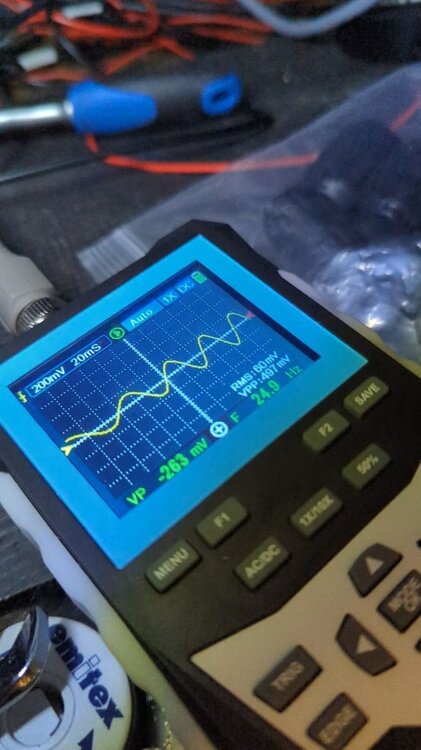

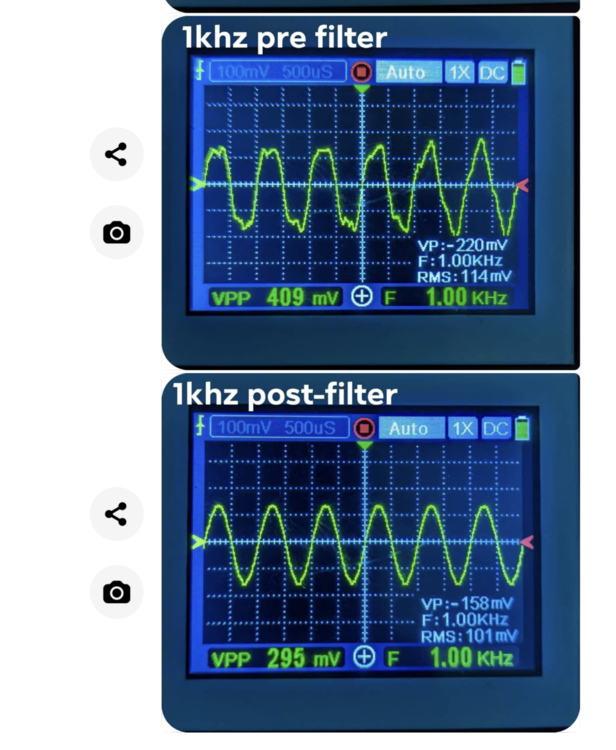

Continuing on the RLTC side of the work... Sadly the used unit I purchased is faulty and the (LONG) story so far on that is here. I completed the wiring install, creating connectors for the interception of the injector wires and splicing into the ABS sensor wires at the rear and running new shielded cable to the passenger footwell. New shielded cable was required as my RLTC ABS portion of the loom was cut and very short. The fault appeared when doing some initial testing and I could see the wheel speed sensors were showing wild fluctuations, as seen below. Keep in mind, the car is on jackstands and definitely not moving when I took these. I ruled out any digital adjuster fault by also checking via laptop and seeing the same incorrect readings. I bought a cheap oscilloscope to troubleshoot the signal coming from the new wires I had run and these checked out as fine and clean. Tested by directly probing the end of my new cable and spinning the wheels with my hands. Clean signal shown below of speed change as I spin the wheel.. At this point I thought it was electrical interference and came across some filters that someone was producing in Germany years back to deal with this issue. For those interested you can read his write up on those here: mounting_traction_control_v2.pdf (lotus116.de) Our passive wheel speed sensors can be very vulnerable to interference. The upshot is he was able to kill wheel speed reading spikes at low speeds on his unit and set a much lower "start" speed where the RLTC starts to function. RLTC has a setting where it will ignore the wheel speed below a certain number because interference is particularly common when the signal is weak (low speed). My example was extreme though and less so spikes - more constant wild speeds. I saw this filter was being bundled into group buys over on the Aussie 300ZX forum and widely used over there in our cars, likely elsewhere too at the time? As expected, these filters are no longer available to purchase but the creator was kind enough to provide details in the previously linked PDF so I essentially copied his homework on this to attempt to recreate it. From what I came to learn of the device, it is a low-pass filter which was designed to filter out noise outside of the expected signal range of the wheel speed sensors. Through the process of recreating it, I realised it was not really fit for our cars and, in my opinion, potentially dangerous. His calculations for the components in the filter were based on the VX220 speed sensors - which have far fewer teeth than our cars. Essentially, he figured out the reasonable range of the signal in Hz based on the number of teeth on the sensors, the expected top speed and wheel circumference and then designed the filter based on this. He had some German blogs at the time which I translated, here is the relevant part on his filter design (the 2m circumference must be a faulty translation or typo his side): Our cars have 46 teeth, the VX220 has 29. Wheel circumference is also very likely to be different. I cannot remember the result when I worked it out now but suffice to say that this filter installed on a 300ZX would result in the Racelogic losing all wheel speed signals at a much lower speed than the intended 186MPH. I think it was around 110 MPH or so from memory using my own wheel size, etc. At very least this would disable the traction control but who knows how the system responds to the signal being suddenly reduced when running at that speed and I did not want to find out. At this point I had the Hz range I needed but this was now far beyond my abilities as some redesign of the components in the filter was required. Thankfully I have a mate who is an electrical engineer and was able to calculate and choose the components needed to rebuild the filter for our cars. Due to the interplay of the components and the components actually available to purchase, a completely custom Hz range is not really possible. What we ended up settling on was a low-pass filter designed to leave the wheel speed signals alone at anything under around 275 KMPH on a 300ZX. Excuse the ugliness - It does not look pretty at all, but I don't think that matters. It was made with connectors so it can be easily added or removed in-line on the ABS sensor feed to the RLTC. I did some testing outside of the car by rigging it up to some the speaker cables for my TV and playing sound tests from YouTube. You can play sound files at a set Hz and this will be seen on the speaker cable and the filter was found to be doing its job within the Hz range we need. One big bonus I noticed was significant smoothing (of the speaker signal at least) within the accepted range of the filter. Below is a screengrab of pictures I sent to my friend who picked the components that show this. You can see the signal smoothness of a 1000Hz signal before it enters the filter and then after. So it was all looking great and I was hopeful this would help but when attaching it in-line on in my car... the problem of wild speed signals persisted. This was the case even with no ABS wire connected to the RLTC loom. I then reached out to RaceLogic and they advised me these are (of course) end of life. Eventually though they did offer to take a look for me but I would need to pay for inspection, labour, components, etc and there would be no guarantee of fix with it being end of life and lack of component availability. To be fair to them, they were very reasonable if eventually offering to have a look when it was not initially something they could help with. By this point I was obviously determined to solve the issue so did send it off. They came back with the following: Again, Racelogic were doing their best for me and through some further emails they agreed if I could somehow source the processor myself and get it to them, they would attempt replacement and repair. I will not bore you (anymore than I already have) by detailing the process to trackdown these chips (had to be be new and unused, of course). I was eventually able to source some from abroad and yesterday forwarded them onto Racelogic. Fingers firmly crossed this will finally solve it.

-

I'm chSing an oem Power steering cooler please help.

Will be interesting to see the final product, whether a cleaned up original or a reproduction!