Everything posted by nickz32

-

Where have I gone now?

I can feel a summer jaunt to the island coming on

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

July 2017 With the car now fully mobile and driveable it MOT’d it for the first time in 4 years. It had a bit of an issue with its headlight aim but otherwise it flew through. Another little proud moment for me was the result of the emissions testing. It goes without saying that I don’t have catalytic converters, yet it only produced 0.75% of Carbon Monoxide (upper limit is 3.5%). That wasn’t the best bit... Hydrocarbon reading of 63ppm (upper limit of 1200ppm). This car burns ZERO oil! Can’t beat quality machining. Another benefit to this is that burning oil lowers the knock limit of a combustion cycle. Therefore a lack of oil in the combustion cycle means I can get closer to the engines theoretical ignition advance limit before encountering knock....... wins all round! I still hadn’t decided what I was going to do on the bodywork front, so I decided that I would take the car to a number of bodyshops to gauge opinions and prices in order to make an informed decision. I honestly had forgotten how much I enjoyed driving a Z. Even just pottering around it put a smile on my face. I resisted the urge to give it a boot full until I’d tested the fuel setup on the dyno, but even with the odd squeeze of the throttle it felt like a puppy wanting to be let off its lead, keen to let rip down the road. I will freely admit that, when it’s all tuned up and finished, I’m a little nervous as to what it will be like to drive. I’ve pretty much decided that next year I’m going to do a couple of Airfield based track days to reacquaint myself with my car and how it feels after all the changes I’ve made. Anyway, the car sudden developed an electrical fault (which I posted another thread about). The speedo would intermittently die and the power steering would load up. Speedo converter was the likely culprit, so out came the dash Something else I will freely admit, I SUCK at automotive electrics, I don’t know why but it’s something I’ve never managed to get a handle on. So I drafted in a mate who is very very very good with them and set about swapping it for another Unit. During the diagnoses state, we’d noticed that the Haltech was receiving a speed signal of about 11kmh when the car was stationary. So I chose a replacement converter that had the facility to send an unconverted signal back to the ECU. This meant both the Haltech and the power steering and hicas ecu’s saw a signal as Nissan intended rather one that had been altered. It appears that I’ve been driving around for all these years with the HICAS adjusting at vastly different speeds to what is intended. Once wired in, a quick check of the Haltech showed a stationary speed of 1kmh. A bit of recalibration will be required to get it bang on accurate, but I’ll save that for the dyno. Annoyingly it doesn’t appear to have completely solved the problem. When I first start up the car and initially manoeuvre at slow speeds, the steering is nice and light as expected. Once up to speed it loads up nicely, but as I slow down again it stays loaded up, especially on right hand turns. Something deffinately isn’t right, but I know the car needed it’s geometry sorting again. Once everything is pointing back in the correct directions and angles, I’m going to have to go through the power steering system and make sure all the solenoids are behaving as expected etc. Speaking of geometry, I was getting a little fed up with bloody rose jointed suspension components! The rear camber arms had a little bit of play that was coming from the rose joints. Time to get rid of them and the nasty driftworks arms that i had fitted many moons again. A bit of research around options for adjustable poly bushed arms and I pulled the pin on a set of these: I’ve always rated White Line suspension components, and these are no exception. Such a shame they make so little for the Z32. I plan on replacing as many of my adjustable suspension components with bushed items to help get some of that silky Z32 ride quality back into the car. I’ve always felt that the Z is a GT car, a sporty one, but still a GT car. And that’s what I’m going to try and stick to when it comes to the chassis and interior aspects of the car. It needs to be comfortable for touring in, but capable with things get twisty and hairy. To add to that interior feel I decided to get rid of my Veilside evolution gear knob. As much as I liked it, it was like changing gear with an icicle in the winter and a hot coal in the summer. I’m similar to Joely, Andrew, Fungal and others in that I like the OEM+ look. While I don’t think my car will ever be an OEM+ car due to the extensive modifications, I take inspiration from the ethos around it. So I chose to go back to an OE gear know with red stitching I plan on keeping the interior very close to stock, Bar the wheel and gauges, as I think Nissan did a cracking job. One day I’ll look at changing the materials on some of the surfaces, but that’s in the very very distant future!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Incredibly flat, no real clarity but no proper distortion. Even at low volume you could see the illumination of the headinit flickering when it was trying to drive the base and then if you turned the volume above 18 (which isn’t particularly loud) the head Unit shut itself down. We tested them on the amplifier we have at the workshop and they sounds a million times better

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

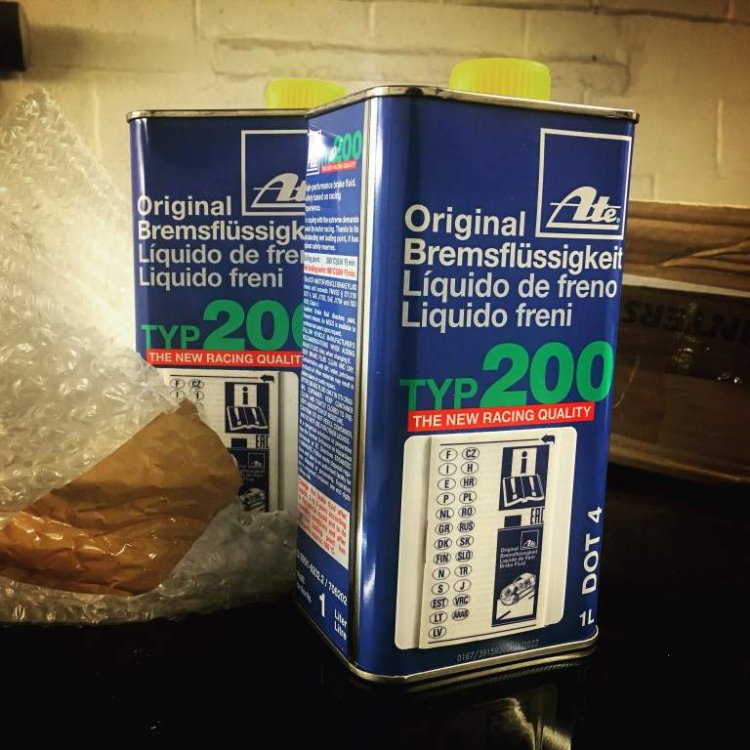

JULY!!!!!!!! 2017 Yes, flipping JULY. A whole 7 months to the day after the go ahead to make the real things I finally got some shiney bits of billet in my grubby mitts Like a kid in a candy shop I whizzed over to the workshop and fitted them. Happy bunny. Fitted a set of EBC BlueStuff NDX lads after some good reviews by a number of mates and the whole brake system was the flushed, refilled and bled with ATI SuperBlue (which oddly isn’t blue anymore) I was hoping to brakes that feel like my wife’s BMW 4 series M-sport that has similar brembo 4 pots fronts/2 pot rears. Didn’t quite work out that way. I took her out for a spin and wow were they bitey! However once I’d bedded them in, they were a lot better. The bite is a bit to close to the top of the pedal for my liking, but there is absolutely no doubting the stopping power these have. Super impressed, but they still need work. Too little pedal effort is required to get them really stopping, which makes modulation of the pedal a little difficult. I’m not used to it, however I know if someone else drives it as it is, they’ll end up head butting the windscreen! I’m now on the hunt for a new engineers/CNC machinist to make something for the rear brembos. I want to see if having the rear brembos on calms the biting point and lack of required pedal effort. If not, then I will probably look at down sizing the brake master cylinder. Muchos ponderings to be had! Still, they look bad ass behind my wheels

-

thinking of getting back into a zed...

Welcome back to the fold!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

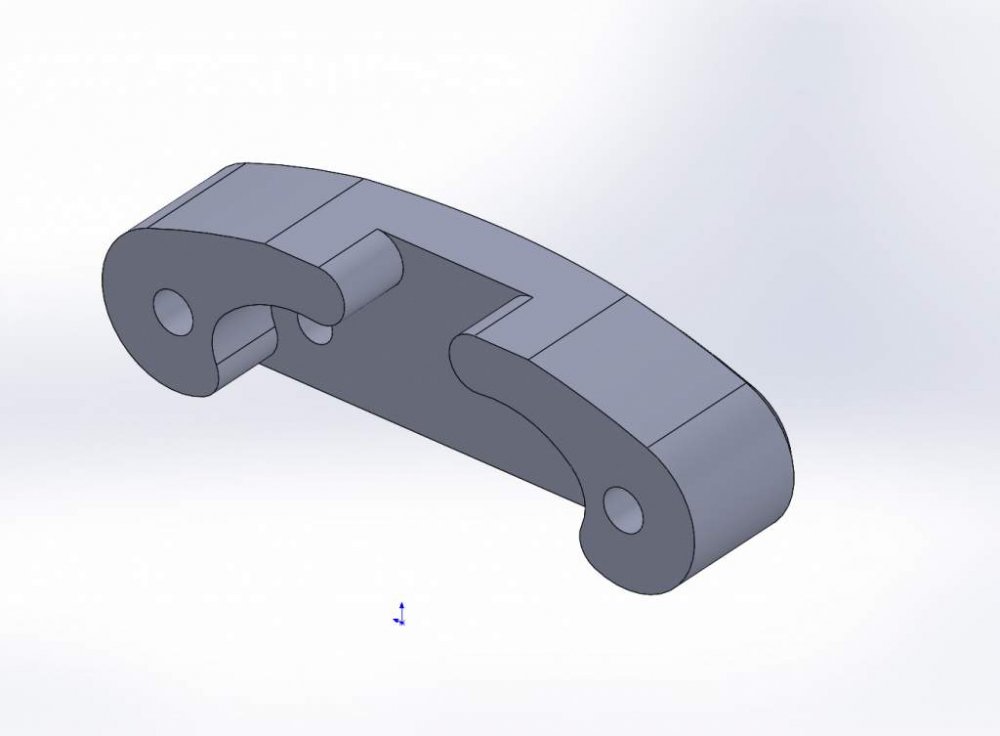

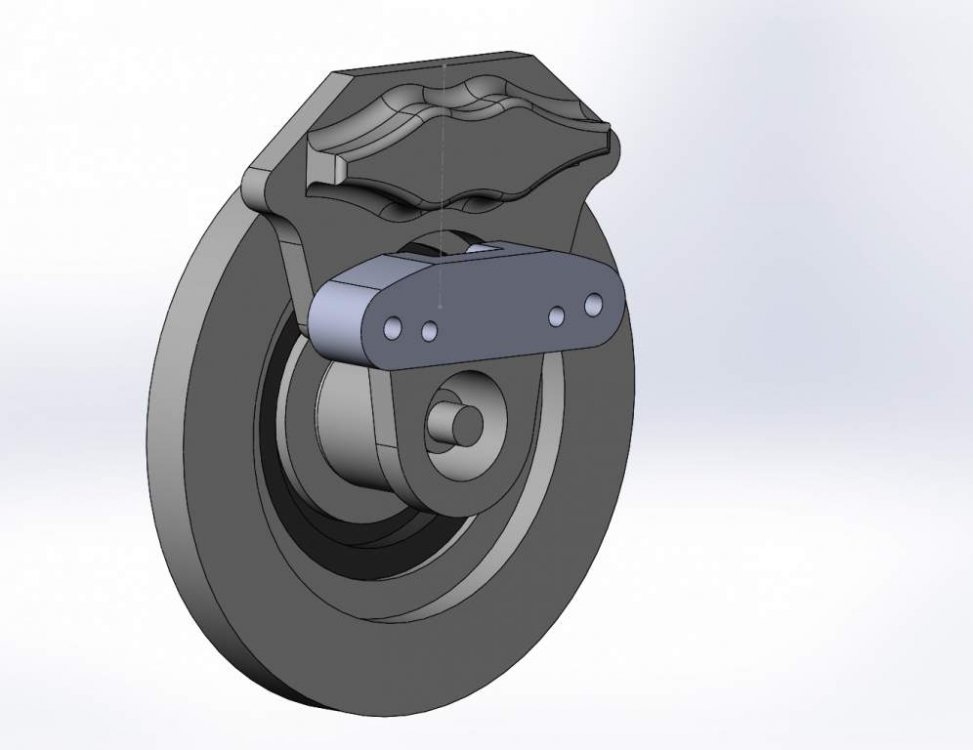

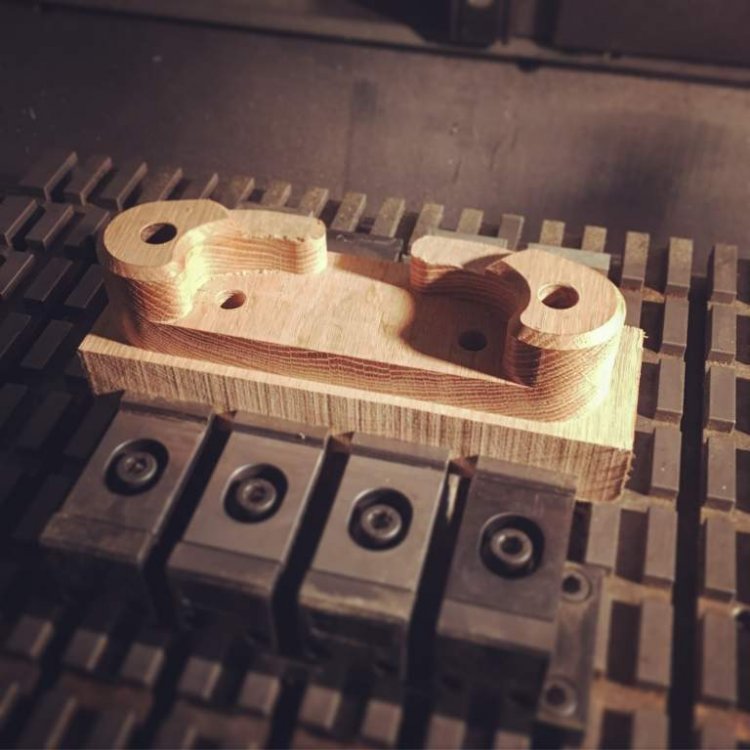

JANUARY 2017 What can I say, I picked a very very lazy CNC machinist! I won’t got into the finer details, but after lots of tooing and froing and arguement, I FINALLY got a design for my brake brackets (a 7 month wait!!!) The combo of Evo X brembos and 370Z discs did cause a slight issue in that there was only 7mm of space for a bracket to fit between the calipers and the mounting lugs in the hub... certainly not thick enough to last a 180mph plus braking situation in a 1600kg car! But I’d committed to buying the parts I had and pushed forward with the guys to engineer a solution to the problem that would be strong enough to take anything I could throw at it. And here it was One sturdy bracket to be made from billet (I forget the grade, but it’s something like Alpan T56, but don’t quote me on that). The backer would sit behind the hub lugs and wrap around it making a very strong piece of engineering. The fitment was designed to be extremely snug against the hub lugs to share the load across the entire hub lug rather than just around the mounting hole. This would require the casting marks in the metal of the hub to be sanded down a smidge as their could have been very small casting differences between the Spare hub I supplied to them to those actually on my car, so s little bit of care and attention was needed to get the fit right. 12.1 tensile grade bolts would be used to secure the bracket. A few days later a prototype was CNC’d out of a bit of hard wood they had laying around. Which was then test fitted to the caliper There needed to be a bit of an adjustment to the design as the support webbing on the rear of the caliper fouled the top edge of the mating sufrace of the bracket causing the caliper to tip forward away from the bracket. A 45 deg chamfer was added to the top of that surface to clear the webbing and it was time to test fit to the car A couple of small adjustments were required to ease fitment, but otherwise the prototype was proven and the go ahead was given to make Version 2 of the bracket out of billet.....

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Something else that’s been on my hit list for quite some time has be audio related. The “sound system” in my Z has been dire since day one, so I thought it was about time that I did something about it! I managed to source a set of Bose speaker boxes from a mate of mine, banzai beakers, and set about removing the old Bose sub ohm speakers for something my head Unit could actually run. I’m a bit like Fungalbumpkin himself and I like Alpine audio equipment. So a set of Alpine SPR60C 130W RMS component speakers went in the rear with some new acoustic packing, with the tweeters nestled away by the rear quarter windows (I’ll take a pic and add it to this thread when I next get chance, but it’s nice and subtle) And a set of MB Quartz 10cm 100W RMSspeakers replaced the Bose 10cm in the front Another leaf I took out of Funky’s book was an Alpine in-line amp . A nice little solution to not wanting to mess around with an amp in the boot (I have other plans for the space under the false floor) And provides 45W RMS to all 4 corners, more than enough to provide a vast upgrade in acoustics to the three knackered stock sized speakers that this lot replaced! And the resulting sound was..... crap. One of my closest friends works with AV equipment ALOT and he’s pretty convinced that the internal amp inside my old Alpine head Unit has seen its best days and given up the ghost. So a new version of my alpine head Unit is now on the shopping list!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

June 2016 With the brembos, disc and hub dropped off to a machinist I tackled a few of the smaller, cheaper jobs. First on the list was oil change. I’d run the engine in on Millers 10w40 CRO running in oil, changing after the first 300 miles for more of the same. At 600 miles I changed to a 10w40 mineral oil for 500 miles (1100 miles in total on the dyno!). Now it was time to switch to my chosen fully synthetic. Again, after a few conversations with Mitch I went with his recommendation. I’d noticed during my top speed runs that oil temps were getting up to 115c or so, and even though I’d updated the oil cooler to a Stillen item I thought it best to have an oil that remained thermal stable and kept its viscousoty at higher temps (rather than becoming as thin as water) aswell as working at temps as low as I was likely to use the car in during UK winters, so a 20W60 fit the bill nicely As you may have already noticed, my boot floor and tank lid were a little on the crusty side. I’d had a leak in the boot somewhere during its 2 years off the road which had popped in the spare wheel well. So out came the wire wheels and etching primer to make it look a bit tidier The last little job was to get the front bumper back on. I knew I needed to do something with my side lights as I’d installed fog ducts, so I went down a fairly common path and converted the turning lights in the indicator cluster to side lights. Bit of a rewire later... I’d noticed the bonnet wasn’t sitting as flush as it used to, so at some point it’s been jacked up on the radiator support (not by me I may add!) which has pushed things up a little. I’d also started thinking about the bigger picture for the bodywork side of things, whether just to get the defects I knew of sorted or to bite the bullet and go for a full glass out respray. With finances as they were, the repair defects was winning that arguement! It was nice to see it in one piece again though!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Aaaaaaah. Interesting. I hadn’t seen that thread..... dual intake it is.... something else for the shopping list!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

The MAF is actually redundant now (I sold it not long after I took these pics) as I’m using the MAP and Air temp sensors for air metering. I managed to find a chap in the Czech Republic who makes Z32 MAF adapter brackets, so I could bolt my air filter to the bracket and then clamp the T pipe around the collar of the bracket (you can kind of see in this pic) I’m planning on doing a bit of testing when it comes to the final tune to see what exact gains are had by going from my T setup (sans MAF) And a dual intake. I know everyone says it’s a restriction, but I’m yet to see any back to back comparisons without additional mods being included in the testing. Whichever comes out as best performing I’ll stick with

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

As and when our paths cross again, more than happy for you to come for a ride And thanks all for the kind remarks

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

I’d placed an inline 30micron fuel filter in line and under the car, which freed up space for the pressure regulator to live. The basics layout looked something like this I wanted to keep the engine relatively stock looking and didn’t want pipes all over the place. So with a bit more work it ended up looking like this After a few teething issues that just required a couple of fittings reseating onto the fuel lines, the new fuel setup was complete. The lines themselves would be able to flow enough fuel for 1000hp with the right supporting bits like pumps, swirl pots etc and injectors. But as can happen, funds had been spent and I needed to save back up. So in the mean time I set about sourcing a CNC machinist to fabricate the brackets for my brake conversion. Oh, and for those wondering, the cam covers are remaining off for the time being. When it comes to the final tune I want to explore what gains can be had adjusting the valve overlap while retaining the stock cams. When the final tune is completed, I’ll look at putting some back on

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

April 2016 I finally get settled in the new workshop/man cave/place of much cursing. To finally have somewhere I could work on my car in the dry all year round was sooooooooo nice! An all too familiar sight now. But needs must! I’d decided on how I was going to modify the fuel delivery system to A) be capable of delivering more fuel than I was capable of requiring and B) to minimise pressure drop from tank to regulator. One crude drawing later... I’d decided that I wanted to run the stock rails in parallel to reduce pressure drop across the rail. I’d adapt the rails to accept AN fittings, aswell as adapting the tank lid to facilitate both feed and return in the size I had chosen. I bought some weld on stainless steel bosses and set to removing the old fuel lines The bosses were welded to the tank lid and rails, with the rails pressure tested up to 6 Bar for leaks All my fittings and hoses turned up a short time after. I decided to route the feed and return hoses along the same path as the OE lines took using P clips and rivnuts to secure it to the floor of the car.

-

This week

Looking tidy

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

This is where my “optimised” ethos progressed into more of a “optimised to 80%”. I no longer wanted to push every component to what it was capable of, I wanted components to be able to be capable of much more than I planned on throwing it them, which in turn left plenty of margin should something unexpected happen. At the same time I also wanted to see and show what a small turbod VG30 (GT525 .54A/R are only a smidge bigger than Sport 500’s afaik) could potentially do. I wasn’t dead set on a peak power number (although I’m hoping for close to the 550rwhp mark) but I knew I wanted it to deliver power in the same way it did when bone stock, quick spool with loads of low and mid range grunt with a nice rush towards the redline at the top end....... just with more! I’m going to have to think of a new ethos name as “optimised to 80%” sounds a bit gash! Suggestions are welcomed! Even thought there were still issues to be solved, I was pleased with how it had performed so far. The previous setup made 570hp and 480lbs ft (6850rpm power and 5800 for torque), so my eyes in terms of how I wanted it to deliver its power it smashed the old setup. To gain OVER 100ftlbs (with more to come) at such low RPM and for it to consistently out torque the old setup through the Rev range with just 0.5mm bigger pistons, 0.5mm bigger valves and some clever machining of the heads and block I have taken as a significant personal accomplishment knowing that I built it. Oh, and I know this is a journal and all. But everyone, please feel free to comment or ask questions or critique anything I write.

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

March 2016 The mapping process had finally properly got under way. Fuelling cells were being written through the load and rev range and an actuator boost map of 9psi was showing promising signs of 430hp and just over 400 lbs ft of torque. However there was the merest hint of a fuel pressure problem. It appeared that the fuel pressure reg wasn’t matching the fuel pressure to the manifold pressure. The data logs confirmed this. Investigations started at the pump, a new AEM 320LPH item. I removed the feed line from the tank lid, gave the pump 12v bolts and measured the amount of fuel it pumped over 1 minute. Multiplied this by 60 to give me how many Liters per Hour, bang on the money of 320LPH. So it wasn’t a supply issue. Air Fuel Ratios were bang on, so the injectors weren’t dumping fuel, but I checked their resistance just in case. Well within spec. Next port of call was the fuel filter. It was only 3000 miles old and I knew that the tank wasn’t full of debris as I had filtered what came out of it during its removal when I had completed the underbody work. But, it’s a cheap enough part, so a new one went in. The problem remained. Next on the list was the fuel pump controller as these have a reputation for failing. Having read Nick Letsom’s blog on the CZP site around the current draw issues he was having with his Walbro, I decided to go along the same route. A more suitable gauge wire was selected (I can’t remember what gauge, sorry) and an independant loom and relay fed the pump directly. I’d noticed the electrical contact points on the tank lid were a little one the crusty side, so I decide to bypass them completely with an ATL CLUBMAN electrical bulkhead connector, which was designed for that exact purpose A bit more dyno time with the boost turned up some more and the problem became more apparent, to the point that after a couple of back to back runs, fuel temp had noticeably risen and pressure had dropped down to 2bar. Thank goodness for the engine protection systems on the Haltech keeping constant overwatch and triggering “safe mode”! Here’s a screengrab of the data log that showed what was happening. The red line is Manifold pressure, blue line is Fuel pressure and the peachy colour line is the Injector differential (this is meant to stay steady at 3bar pressure at all times). So as manifold pressure goes up (boost) fuel pressure should match it exactly, while on this run fuel pressure was up to 8psi down from where it should be. So the next port of call was the pressure regulator itself. The car had been running a Tomei Type S fuel pressure regulator. A reputable brand and a genuine part, hence why it ended up being one of the last thing we checked. I swapped it for a SARD RJ that the tuner had floating around. Once fitted all appeared to be ok. Back onto the rollers and good progress was being made. At around the 1.3 Bar of boost level the mapper told me that he’d hit a bit of a wall and it felt like something was holding the car back. The car had developed what can only be described as a goose honk type rattle noise towards the rear of the car. Off the dyno AGAIN and on to a ramp to investigate. A bit of prodding and poking later and the source of the noise was found to be one of the silencers in my Kakimoto H pipe, a part that has been on the car since it was imported. It was swiftly removed and TWO issues were discovered. 1) the baffle had collapsed in one of the two silencers, the source of the rattle 2) while the pipes going in and out of the silencers were 3in bore (as per the rest of my system) the internal diameter of the pipe going through the resonator was only 2inches. No wonder the bloody thing couldn’t breathe! Out they came and were replaced with 3in ID silencers and back on the dyno she went. More progress. Now up to 1.6 bar of Boost (pretty much the max you can get out of GT525 .55A/R turbos) and 556hp at 6800rpm and 589lbs ft at 3850rpm (and never dropping below 500 lbs ft all the way to the red line) while still on the Haltech base ignition map and no VTC activated. Things were starting to look seriously promising. And yet, annoyingly, fuel pressure issues kept reappearing especially at fuel levels of less than a third of a tank of fuel. Which lead to this thread I posted https://www.300zx.co.uk/forums/showthread.php?184804-Stock-fuel-system-limitations-at-high-HP After a lot of time in the dyno, it was time take the car to my newly acquired workshop to tackle the fuelling system.

-

Pistonheads Little 300zx Writeup

Nice to see it get a mention Cue the on going arguments about Z prices....

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Feb 2016 Finally, she was all set for the dyno and set to make some power. A couple of preliminary runs showed everything to be in fine fettle, Bar the annoyance of a VTC rattle appearing when cold..... or so I thought. One bright winters morning I turn up to the dyno keen and ready to learn more about the processes of mapping a car. I did a few pre fire up checks on the fluids and tyre pressures and fired her up to start getting a bit of temperature in the engine. Nothing appeared out of the ordinary, including an annoying cold start VTC rattle, so I wandered to the kettle to make a brew. Within a minute or two there was a very audible rattle, a loud clunk and the car running like a bag of turd. I ran back into the dyno cell to turn off the engine and then sat down in complete disbelief. As far as I was concerned something had gone wrong and the engine had disintegrated. The sound I heard was incredibly similar to the sound one of my old 205 GTI’s made when it launched a piston through the bonnet many year ago. I had a look around the engine, temps were normal on my Defi gauges, no fluid coming from under the car. What the hell was it. So I sat and sparked up a cig for the first time since my knee op 13 months back.... and another..... and another. The company boss/mate of mine James turned up and said I was white as a sheet. Utterly utterly gutted. So after more nicotine and caffeine, we rolled her off the dyno and into a spare space in the workshop and I was convinced to investigate what had happened rather than my suggestion of burning the bloody thing. So, I popped out the spark plugs expecting to find mangled metal..... nope Off came the timing covers....... ah ha. The intake cam on the 1/3/5 bank had skipped over 90 degrees out of position. Bugger. So, out came the engine AGAIN to see what the damage was. Onto and engine stand and I start stripping back the front of the engine. Off with the offending intake cam pulley and I find The back of the intake pulley was gouged to hell, but where the hell had they come from???? Well, the backing plate that sits behind the cam pulleys. It transpires that the only two bolts I hadn’t loctited (and more than likely double checked tightness after loctiting) were these two bolts. They had vibrated loose and jammed the pulley soild. I had a look at the belt, not a single tooth missing (bloody strong those things) but the tensioner has been pulled out position on its mounting tabs. At this point I was completely convinced I’d find at the very least a mangled set of new valves and a head. I stripped off the remaining parts I needed to check the valvetrain. Every single valve was as straight as a arrow on initial inspection. But I wasn’t willing to take any risks. So off came the head. Piston crown was damage free and there was nothing visible on the valves. Popped out the valves and checked them for straightness, all good, as were the valve seats. Utterly gobsmacked. Somehow I’ve got away with it. The only theory we came up with was the cam stuck itself at a point where valves opened at a different stage of the stroke where the piston wasn’t at TDC and the exhaust valves were clear from interference. The odds were astronomically high for this to happen, but there simply wasn’t any damage to be seen. One lucky Mo Fo! Head went back to the machine shop to check for straightness as surface quality and a new head gasket and another Kevlar belt was ordered. However, it was obvious I needed to replace the intake pulley, so I purchased a set of BDE adjustable intake pulleys, which have stronger internal springs designed to cope with heavy duty valve springs. Put her back together triple checking EVERYTHING, fired her up and she ran like a dream. Phew! Lucky boy!!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

January 2016 Before putting her on the dyno for its tuning session I decided to look at removing another bottle neck in the system, being my Z1 SMIC’s. I was aware that some 2.5in inlet/outlet intercoolers had come onto the market, but I’d decided that I wanted the new ducts in the front bumper to be used to cool the brakes, so having taller intercoolers wasn’t possible. Instead I decided to convert my current SMIC’s to 2.5 inlet/outlet and use front and rear ducting on the intercoolers to help guide the air in, through and out of the intercoolers as efficiently as possible. So off to the fabricators again OE ducts were refitted to the front of the intercoolers (with a bit of trimming required) and ponderings around how to help the air out of the back of them. Obviously the washer bottle/Carbon Canister/Screen was bottle make like very difficult. The current thinking is guiding the air into the undertrays so that the passing air under the car draws the air coming through the coolers out and under the car. As it currently stands, I’m still at the pondering stage of this development

-

The biggest upgrade I have ever bought my car!

Honestly mate, if you’re aiming for the power levels you want I would suggest in the strongest possible terms you look at a standalone ECU. Yes it’s expensive, but with key sensors and a sensible engine protection setting it will save an engine when something unexpected happens.... and they’re a dam sight cheaper than an engine rebuild. On top of that you can have features like Boost by gear to optimise traction in each gear, traction control, antilag (if you’re that way inclined), flat shifting etc etc etc Learn from my mistakes mate. Just because a stock ECU can be tuned to provide X amount of power, doesn’t mean it’s the right tool for the job Just my 2p’s worth Cracking garage aswell!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

October 2015 She fired up on the button on Haltech base map and everything appeared hunky dory. Off to Rabbid Tuning in Basingstoke (my local Haltech distributor and tuner) Basic health checks were completed to make sure everything was all good and problem number one appeared. The base ignition timing was wandering by up to 5 degrees, which in turn was causing a fuelling imbalance between the two banks. After checking the cas, timing markings and verified what the Haltech was seeing with a timing light my attention was drawn to the timing belt, which appeared a little slack. The timing belt was a brand new OE item and the tensioner only had 3000 miles or so on it. Having looked at the tensioner I reset the belt tension as per the manual and span her over and noticed that the tensioner was struggling to maintain belt tension. After a loooong conversation with Mitch at EPR, we concluded that the most likely cause was down to the new valve spring setup was putting extra strain on the tensioner when the cam was compressing the valve springs. This was pulling the tensioner piston into the tensioner. When the cam released the compression on the spring, the tensioner couldn’t react quick enough to take the tension back up on the timing belt, which in turn was causing the timing to drift on the CAS. An EPR Racing manual tensioner and a Power Enterprises Kevlar timing belt later, rock solid base timing And there I was hoping that this would be the end of the issues..... I was in for a rude awakening and a reminder of my amatuer status

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

A bit of a photo dump from the rest of the rebuild. Nothing particular of note Bar how much I enjoyed doing it (Please excuse the photo rotation, for some reason when I attach them thy rotate, not overly sure how to solve it)

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

September 2015 After discovering the damage to the valves and guides the rest of the valvetrain was inspected. This is where we discovered the valve springs themselves were out of spec. Another unexpected expense. So after some great advice from Greg Dupree I decided on a set of SuperTech 0.5mm oversized valves to best match the 88mm piston bore. These would be matched to SuperTech dual coil valve springs and Titanium retainers for a full SuperTech valvetrain. I bought a set of Ferrea phosphor bronze guides to replace the damaged guides (which oddly were only on the intake side). I was advised that it would be best for longevity to keep the cast factory guides on the exhaust side of the head as they are much more resistant to heat than the phosphor bronze items. So the exhaust side guides were rehoned to spec and the new guides fitted on the intake side. The valve seats weren’t in bad condition, but I was starting to find myself aiming towards an “optimised” ethos for the engine. I didn’t want to push more power out of the engine, but I wanted to optimise what hardware I already had. This lead to me to looking at head work. Jimmer had already done some head work on my 48p heads during the previous build, but thought now was a good time to look at valve seat cuts and valve throat work. Roland Alsop introduced me to their Newen Contour CNC valve seat machine. Best way I can describe it is that it’s a step above a 5 angle seat cut. With some clever maths from the guys at Roland Alsop based on their experience the valve throat and valve seat with contoured to maximise flow without hindering air velocity. These throat and valve cuts generally give a 12HP increase on 1200cc Harley V-Twins, so I’m sure it would have a positive influence on my engine. The heads were skimmed and re assembled with the correct valve spring heights set and they were ready to rock Bish bash bosh and the long block was assembled

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

With putting all this work into my rebuild I started to think about how best to protect it from going pop again. Again, I sought advice from a couple of well regarded tuners and looked at the options available to me. I knew the stock ECU wasn’t capable of providing the engine protection that I wanted, after all, under its “watch” I’d detonated two engines. Nistune was initially attractive but at the time of looking it used the same Knock detection range as the stock ECU (which is only capable of sensing knock up to circa 5500rpm) and being a daughter board, not capable of making use of additional sensors. That left me looking at stand alone ECU’s. The three most common available as a “plug and play” option that I desired were AEM, Link and Haltech. I discounted the AEM as it was fairly old tech comparitve to the Link and Haltech And didn’t have the datalogging capacity of either of the others. I discounted the Link as to have full Knock monitoring capability you had to purchase the knock block kit, which to me seemed stupid that an expensive stand alone required extra kit to have full Knock control capability (I believe it’s now included in their g4+ ecu’s). This left me with the Haltech Platinum pro plug in ECU. I decided that I wanted widebands to constantly monitor the fuelling, so I bought the wideband controller Unit add on which used digital wideband sensors via a CANBUS connection. I wanted to go to a MAP setup as my previous setup was close to the limit of the MAF, which meant an additional air temp sensor. Further more, I wanted to be able to monitor fuel pressure to ensure all bases were covered when it came to the fuelling system (as the Haltech is able to read the existing fuel temp sensor, it enables effectively a 3D map for fuelling that covers fuel pressure, temperature and demand). Throw in a 3 Bar boost solenoid and the management side of things was complete.

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

The rest of the bottom end went together smoothly. Bearing tolerances were all at the loose end of the scale, but I was happy with that in order for the bearings to have a nice thick cushion of oil for when things get hot and heavy on track.