Everything posted by nickz32

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

This nicely demonstrates the timing wander you get with the CAS (and this is with an AEM 24-1 CAS wheel, which has less resolution that the OEM CAS disc). Both feeds are taken at circa 6200 rpm. Pink line is CAS, Black is crank trigger wheel [ATTACH=CONFIG]115965[/ATTACH] Think this shows perfectly how much the ECU has to guess what the crank position actually is! With the AEM cas disc, there is s variance in timing of 7.3 DEGREES!! THATS HUGE! The increased accuracy will result in a better ignition timing map and potentially gain a few degrees of ignition advance, and therefore more power and torque across the Rev range

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Bloody iPhone autocorrect!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Been waiting for these to turn up! This means I get rid of the Nissan optical sensor in the CAS, and it allows my Haltech to know an accurate crank position with the timing ring on the Harmonic dampener and a Hall effect sensor. This means more accurate ignition timing, and a better state of tune.

-

2019 National Census for the 300ZX Owners Club

Christ, I can’t believe how many votes this has had. If we had anywhere near these numbers turn up to events, it’d be like the old days!

-

New to the club

Welcome along fella

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

They’re going straight to EPR, so as soon as Mitch posts a pic I’ll share it here

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

I know.... it turns out my work has messed up some of my allowances for the last 9 months, so I got a pleasant suprise this payday... It’s now safe to say I have my dream engine spec

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

A little EPR update. Main caps have been bored and honed. Now it’s time for the cylinders to get the same treatment

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

Sniff test.....damn!

Apparently I clicked WTF on this post..... must have been a fat thumb moment because I didn’t mean to!

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

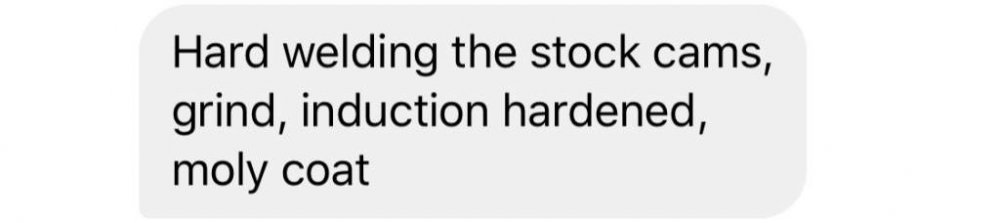

Which is precisely what JWT do, just starting with fresh cores

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

It’s can certainly be a consideration...... although Piper cams were never regarded as top quality products

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Hahahaha..... should have put my glasses back on before typing that :lol:

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

As and when I do change cams, it’ll coincide with changing to adjustable exhaust pulleys, larger TB’s and extrude honing the OE upper Plenum.... but that’s probably some way off. There’s some chassis based “madifications” that are further up my “to do” list

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Quite possible, and they’re then “fully hardened” with some form of hardening process?

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

I was going to guess they were regrinds, but that doesn’t make sense as regrinds usually have a reduced base circle, which the EPR one don’t (they retain the OE base circle)

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

They do?

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

EPR Genesis 1 cams.... 272degree @ 10.2mm lift

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Well I was hoping to give a little update saying that I’ve added a set of camshafts to the spec of my engine so I’m able to take full advantage of my CNC ported head, CNC ported lower Plenum and SuperTech valvetrain...... However, no amount of Man Maths I do can generate another £1500 to go into this build. So for the mean time, I’m having the heads machined for extra lobe clearance, so whenever I can afford to update my cams, they can drop in without the need to remove the heads again for further machining A little gutted, but hey, cant always have everything our way!

-

oil pump failure?

I would say that if your oil pump had failed, you’ve have more damage than just one spun rod bearing. Given how the crank is fed, your Main bearings would had suffered oil starvation before the big ends in the event of a pump failure. Unlike their RB counterparts, VG oil pumps are sturdy bits of kit that rarely fail. However rod bearing failure is a fairly common thing on VG’s. We’re all the engine internals thoroughly cleaned prior to reassembly, including the oil galleys and sludge traps in the crankshaft? What were you bearing clearances set to? What brand bearings were used? Who built the engine?

-

Black Z thread

Meaty

-

JaiKai - MK2 - Ziggy Build

Don’t entirely agree with that. From the video chat we had the other week, it sounds like it’s spinning enough to potentially start, but still sounded like a fairly slow crank over, and it significantly drains the battery after 2 or 3 start attempts. That, in my eyes, is not normal. It may be a symptom of your issue (an electrical gremlin somewhere sapping power and preventing a start) or it may be unrelated... I’m not sure. Once you/we have verified you have a good spark, as Joel says, would be wise to the verify the correct plugs are attached to the correct coils and injectors. We know you have fuel as it floods, so next step would be to check its firing the plug st the correct time and firing the injectors at the correct time. At least we have learned something new, that the fuel pump fusible link is connected to the ignition coil relay.... always thought they were independent circuits!

-

JaiKai - MK2 - Ziggy Build

And if you’re a little confused Lee, JoelyP and i we’re talking about the problem last night.... he’s not hacked your phone or anything

-

Sniff test.....damn!

Honestly mate, it’s easier to pull the engine than it is to pull th with the engine in situ