Everything posted by nickz32

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

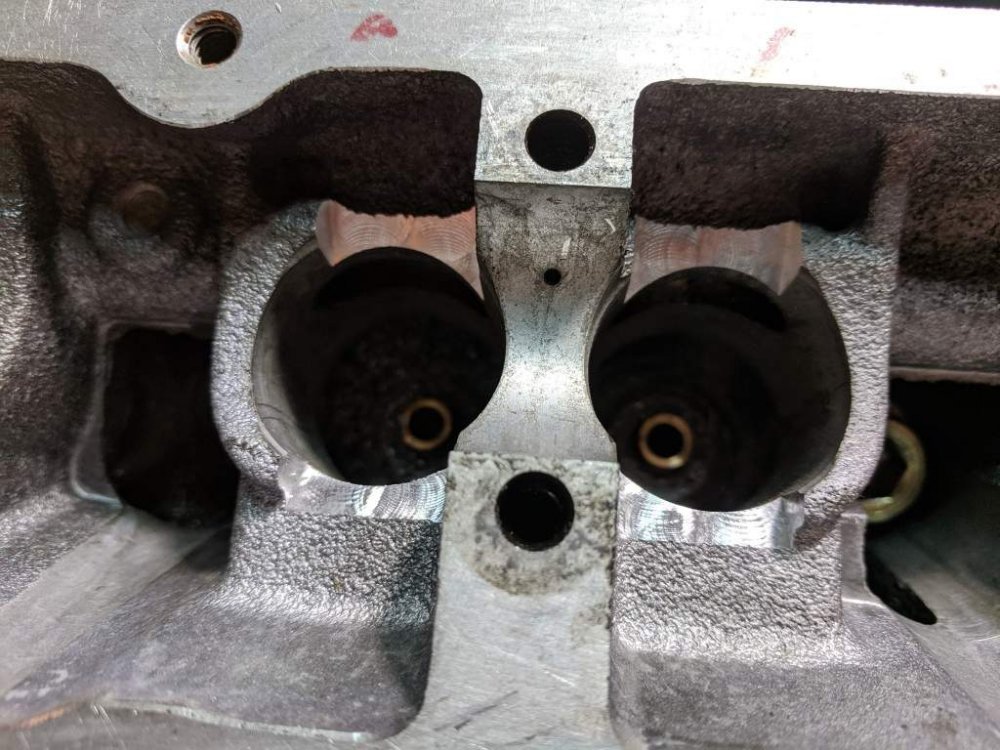

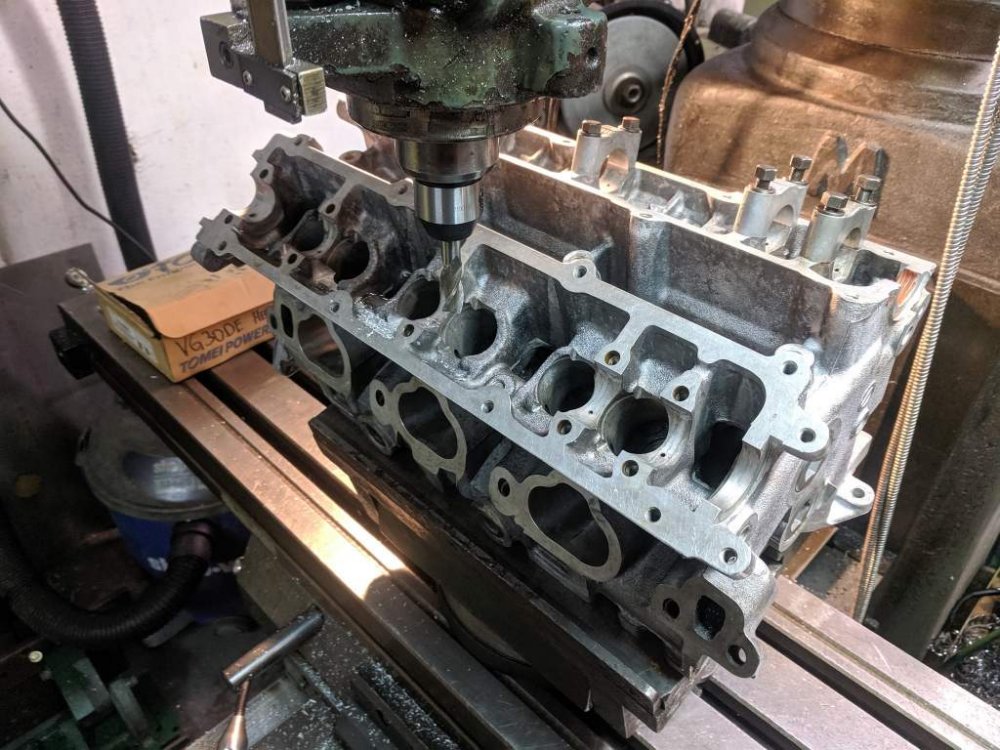

A pic showing the inside of the oil galley that was opened cleaned and threaded that supply’s the lifters

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

So they’ve got a 44 micron stainless steel mesh filter that’s washable. There’s nothing about service life on the bumpf on the website, but I guess you’d just clean them out whenever you did a normal oil and filter change. As for pressure drop, being TurboSmart, I doubt there’s any

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

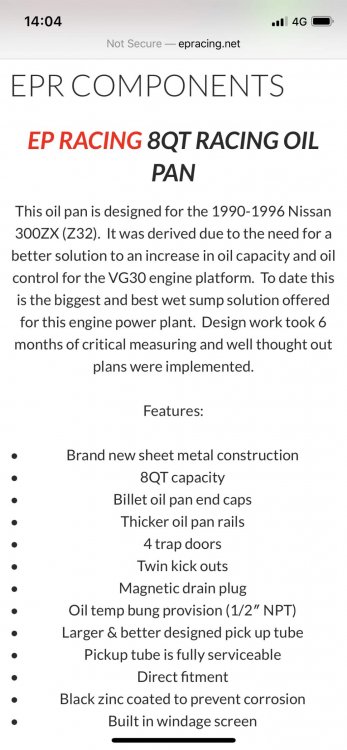

Another new addition that will provide a little more protection to the turbos I’ll be plumbing one of these in the feed line for each turbo. Should anything go wrong in the future (I bloody hope not!) they’ll prevent any debris being sent off to the oil journals and potentially trashing a set of turbos. I’ll need to make up a set of custom -4 braided lines for the turbo oil feeds, but that shouldn’t be too hard to do

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Coolio Yeah it would in an ideal world, but it’s being force fed by a Plenum (not drawn by cylinder vacuum once on boost) that isn’t supplying a balanced portion of air. By going down that rabbit hole I’d be chasing my tail for thousands of dollar more work... kinda gotta stop somewhere. Cheers dude

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

This is the other vid EPR sent me that shows a bent vs straight valve in the same jig [video=youtube_share;jHkHXqaxi3I]

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

He didn’t check them using the lathe, that was simply the easiest method of showing me via video what he had noticed when he had put the valve in the valve grinder. I’m sure there is a more accurate method of showing the amount of bend, but it’s kinda pointless.... a bent valve is a bent valve and needs replacing. Checking the ports volume, probably not as that info doesn’t really assist me in any way. I can’t make use of it for the tuning process as the Haltech Platinum doesn’t allow individual cylinder fuel maps, just injector trim. If I had something like an Elite 2500 or Motec M150, with individual IAT sensors per cylinder and EGT per cylinder then it would be information I could actual use to my benefit. Otherwise it’s just “nice info to have” for me at this stage. I’ll be able to see the benefits/changes in the heads as I’m using VE based tuning rather than Speed Density, so my VE numbers in the map should be lower across the whole map in comparison to my old setup as both compression ratio and engine CC has remained the same

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Nope. It must have just glanced them

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

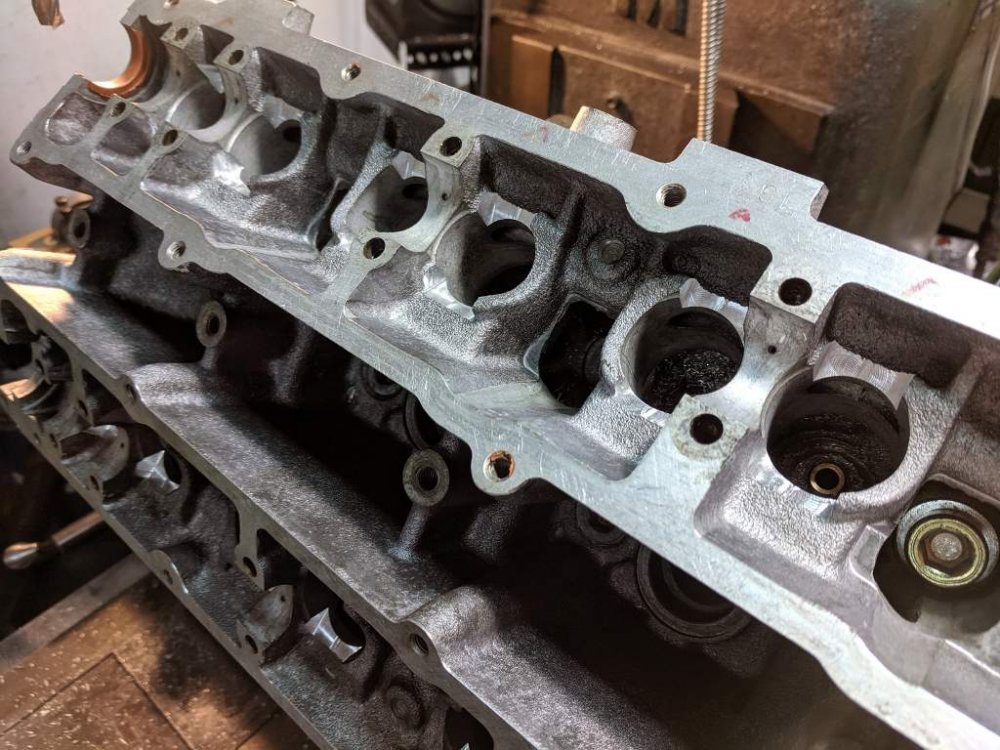

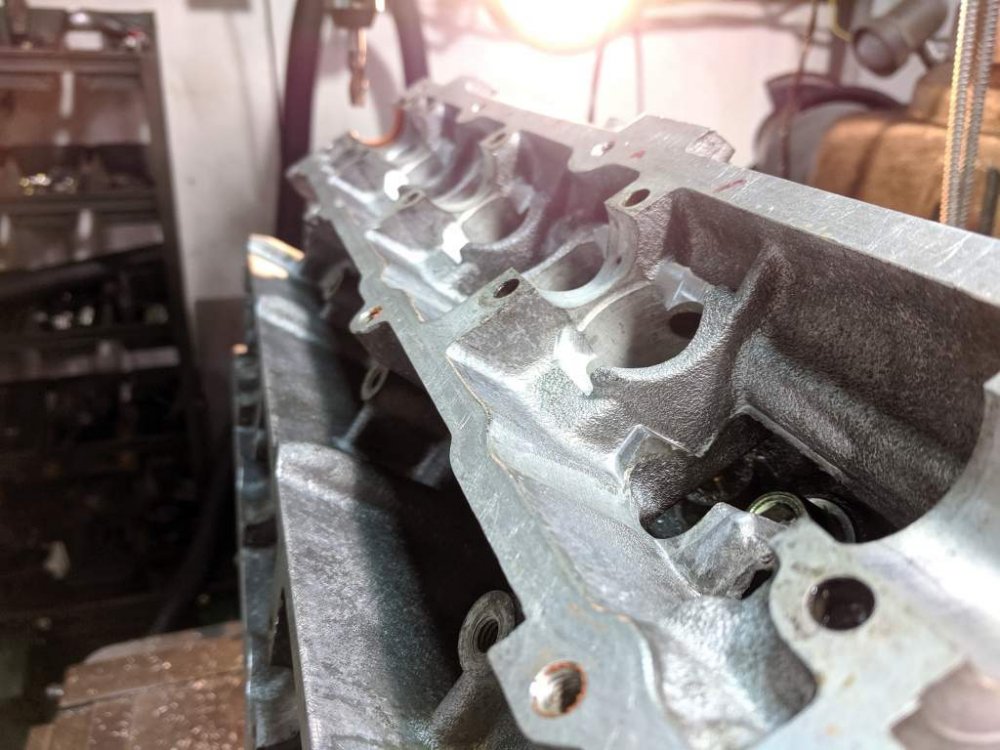

Indeed. The lower Plenum has also been cnc ported. This is done by bolting the lower Plenum to the head to ensure the transition from Plenum to head is as smooth as possible

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Just when the build starts gathering momentum.......I’ll start with the bad news... So for those of you who’ve followed this thread from the start, you may recall a lucky escape I had when a backing plate bolt worked its way loose as jammed itself into one of my intake pulleys...... Post #15 in this thread if you wish to remind yourself. Well it turns out I didn’t get away with it after all! As Mitch has started to cut the seat angle in the valve, he noticed one of the valve wasn’t spinning concentrically in the cutting machine. So he put it on a dial gauge and this is what he found [video=youtube_share;xFHyq-m-pyg] It turns out I have 6 intake valves in the exact same condition... bent. How this car made over 550hp on 6 bent valves is beyond me! Yet again, Mitch’s diligence has made sure that I have a 100% perfect engine and nothing less. So I’ve ordered 6 replacement SuperTech valves from CZP. On the good side, the heads are progressing well. Some before and afters with the head work

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

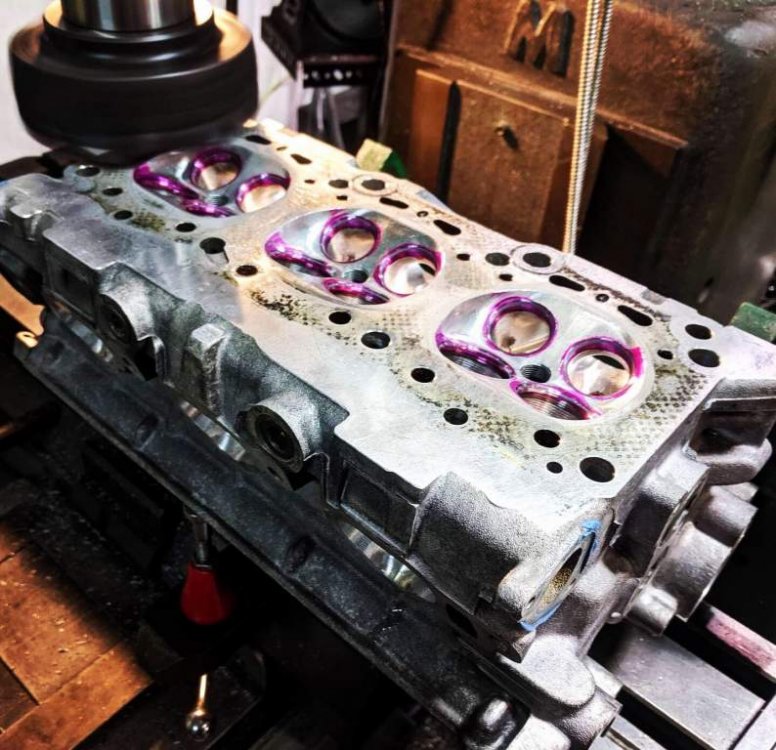

Final stages of the head work are under way! First, lapping the valves into the seats... with a little tease of the CNC work Then onto surfacing the head Leaving something like this And then the small details. This access hole is normally sealed with a solid aluminium plug. It’s an access point into the oil galleys that feed they hydraulic lifters. Once the plug is removed, the galley is cleaned and the port has a thread tapped and a grub screw installed to make that access point serviceable in the future. Things like this really reinforce the decision to have EPR build my engine.

-

Southern end-of-season meet: Brooklands Museum - Saturday 12th of October

1: Funkysi (Simon) 2: AndrewG 3: nickz32

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

Fitting a EBC and a stage 1 remap @ powerzed with Jimmer

I’ll add a quick footnote. As a general rule of thumb the cc Number if the injectors is roughly the maximum HP the injectors will support safely, so 370cc roughly supports max of 370hp, 550cc=550hp max etc etc etc. Obviously there are lots of other variables to take into account, but as I say, it’s a good rule of thumb

-

Fitting a EBC and a stage 1 remap @ powerzed with Jimmer

Where did you get that duty cycle reading from whilst on the rollers?

-

Fitting a EBC and a stage 1 remap @ powerzed with Jimmer

Yes mate, 1:1 rising rate so @14.5 psi boost fuel pressure is at 58psi

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

Fitting a EBC and a stage 1 remap @ powerzed with Jimmer

With regard to injector sizing for boost, the maths don’t lie. 370cc @ 43.5psi injectors x6 2998cc 6 cylinder engine Boost pressure of 14.5psi Maintaining AFR of 11.5/1 At 7000 rpm duty cycle is at 95.25% The general consensus for ROAD based cars is duty cycle shouldn’t exceed 85%. Whilst the flow-pressure characteristics of the OEM pump mean that At 60psi absolute pressure it still flows a sufficient volume of fuel that reduce the risk of running a higher duty cycle for a VERY short period of time, running above 85% does mean that you’re eating into a margin of safety that is there to account for variances in atmospheric conditions including both air and fuel temperatures. To be able to flow enough fuel for more than 14.5 psi, you would have to raise your base rate fuel pressure to effectively force more fuel out of the injector at any given duty cycle. The risk of this is that as fuel pressure goes up the amount of fuel the pump can flow goes down.... you then run the risk of running lean by way of insufficient fuel supply from the pump. When you then factor in that the early style pintle capped injectors are at least 26 years old by now, and simply don’t spray as cleanly or consistently as the newer style pintleless injectors, I would STRONGLY advise changing to the new style Nismo 740cc injectors to ensure safe running at anything above the boost levels Jimmer as set for you.

-

Simply Japanese 28th July - 2019

One was a 240Z from Hampshire Jap Cars, didn’t see what the other was

-

Simply Japanese 28th July - 2019

Nice little show.... didn’t have much chance to grab any pics as had my hands full with the little ones. Good to catch up and chew the fat with Andrew, Si, Ian and Howard. Nice to meet you ThRealNips and Gio

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

I’d like to think it will be ready for shipping at some point next week. The heads will be cam lobe clearance, skimmed, deburred, cleaned and assembled this week, after that it’s install and set the cam timing. Shouldn’t be far off

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

- My daughter calls it Toothless the Dragon: My ‘95 TT Z

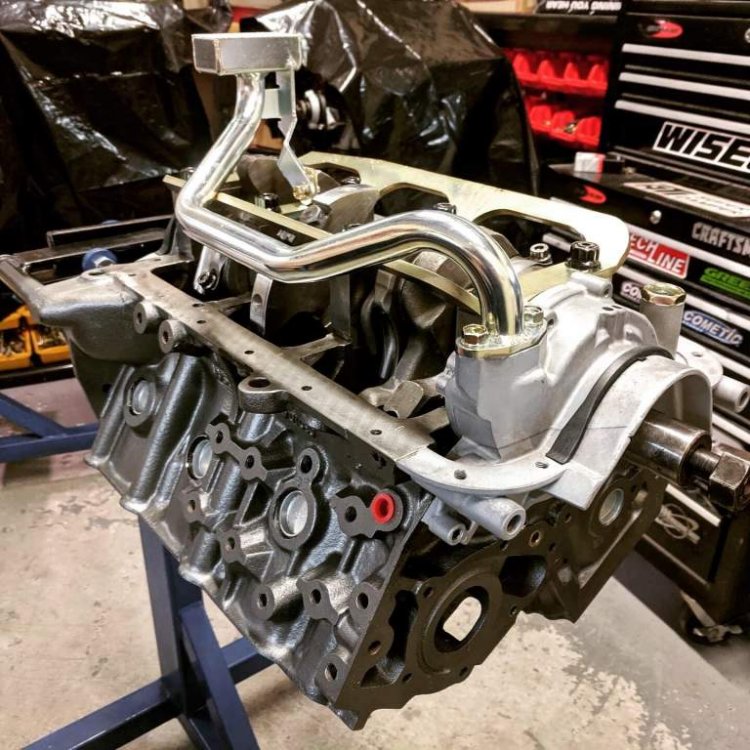

Complete spec: @cp_carrillo 88mm pistons treated with @techlinecoatings black Diamondyze, crown and skirt ceramic coating, @saenzperformance tri-beam forged con rods, @kingbearings XP series mains and big end bearings, @arpbolts 2000 series main studs and rod bolts, EPR Billet mains caps, modified crank, modified oil pump and extended and baffled sump. Also had the waste gates ported an extra 1mm to help reduce the boost creep issues.- My daughter calls it Toothless the Dragon: My ‘95 TT Z

Another little job finished today. Cleaned up the coolant pipes on the front of the engine. Will ceramic coat with the Carbon Collective Platinum Wheels to keep that fresh out of the cast look- My daughter calls it Toothless the Dragon: My ‘95 TT Z

New H pipe has been remade using the 3” Vibrant Ultra Quiets. I always thought my Kakimoto system was 3” bore, but it turns out that it was actually 70mm, so a touch smaller. As I’m still using the Kakimoto rear section, we’ve kept the flanges in the same position and rotation as they originally were. Be interested to see how it sounds now - My daughter calls it Toothless the Dragon: My ‘95 TT Z