Everything posted by JeffTT

-

Interesting afternoon in the workshop...tech thread

Yes cool glad to help, I will continue tomorrow with the job and take more pics when doing the cam end seals too. Jeff TT

-

Interesting afternoon in the workshop...tech thread

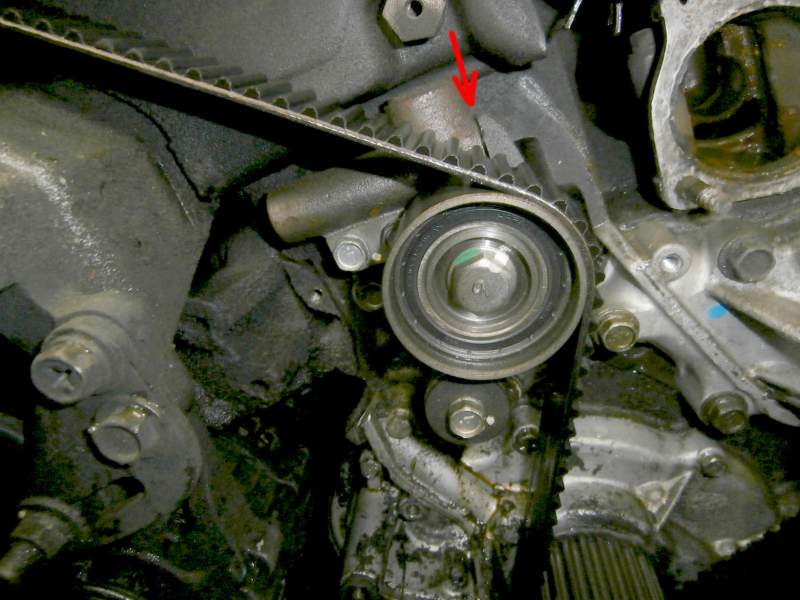

So a poorly zed in for a cambelt + other work, the cambelt was tacked first as clearly the cam end seals were leaking as escaping oil had run down the front of the engine and covered the alternator etc. nothing too bad however whilst in there I did discovered a few Kodak moments........ So once stripped down it seems the belt was not that old looking, however it was very oily from the cam end seals as I expected, however the run of the belt was not to good especially over the lower right hand pulley, closer inspection shows the pulley had been replaced by pressing a new one, however it was on too far and the belt had been running over the pulley by 4 mm or so......not nice. You can see witness marks on the pulley leading edge where the bearing has been changed over on the adapter without the correct tools. So moving on, a nice clean (new? ) belt tensioner was in place but set completely incorrect, a similar case last week was highlighted for the same reason, little point of setting it in the closed position?? So onto the belt itself, if there are still any doubters out there ( sincerely hope not ) the argument for my campaign against non genuine belts is clearly highlighted by this unbranded item, when compared to the genuine Nissan item the belt quality and structure is much superior on the genuine one, given the belt lacked any timing marks I made a tooth count and compared the two belts and although only slight the difference was significant over the 5 timing marks it was enough to be of concern, maybe why the cas unit is so far over? Of course I having a vested interest but I cannot stress enough cam belts change on a Z32 needs to be done by someone familiar with them. Jeff TT 32

-

how to remove ecentric bolt from rear camber arm ?

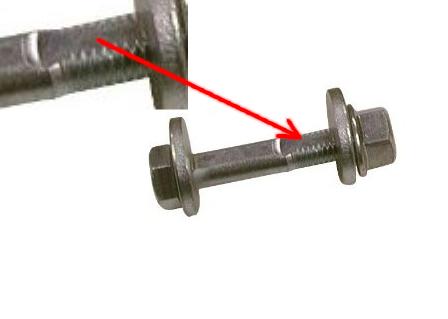

Is the adjusting washer still in place? if you have turned the bolt end and not the nut end the washer gets stuck on the shaft of the bolt as the detent has been forced past the engagement point, if so this needs realigning to get the bolt out The picture is not exact but gives the idea, if the washer has gone past the flat it will be locked onto the bolt, you need to hold the washer with mole grips or similar and turn the bolt until the washer lines up and is released and then the bolt will come out. Jeff TT

-

Question for Jeff - Wiring Loom

Essentially they are the same, however within the TT models there is some slight difference on years such as dim dip on UK cars around 92, and on later import there is an extra connector for the boost sensor by the afm. Non turbo also do not have multi-speed electric fan so connector is different ( more cables on a TT) and the sub and main fan relays differ, but cannot see why with a little work you could swap them over. Jeff TT

-

windscreen tech

BMW E60 2005 onwards. Jeff TT

-

windscreen tech

Not exactly exciting but a sparkly new windscreen just looks so good..... The windscreen top strip is expensive and as an alternative we use a 5 series BMW one which fits perfectly and also looks better than the original one I think and less costly. Jeff TT

-

Cambelt tensioner...

-

Bottom pulley horror

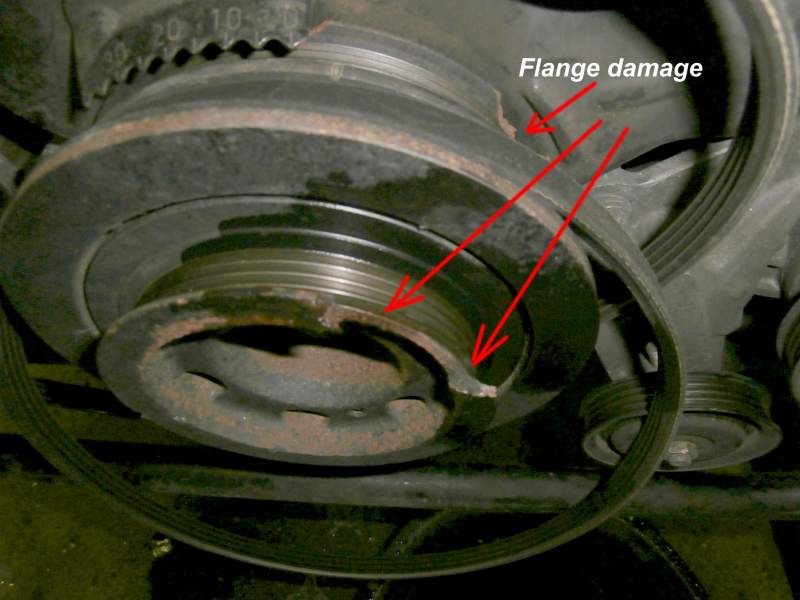

Whilst doing a second cambelt change yesterday I cam across one of the worse bottom pulleys I have seen in a long time, not only was the back section damaged where a previous attempt by someone to remove it wit a hammer but a large section was missing from the front flange, a badly fitted/ used puller seems to have shatters the section clean off!! Of course fitting a good used one sorted it, just bad practice really and feels wrong it spinning around at 5k with a lopsided front...not good. To top it the water pump had a sheared bolt and the loom to the cas unit was unclipped and ready to catch in the fan blade..... Jeff TT

-

Cambelt tensioner...

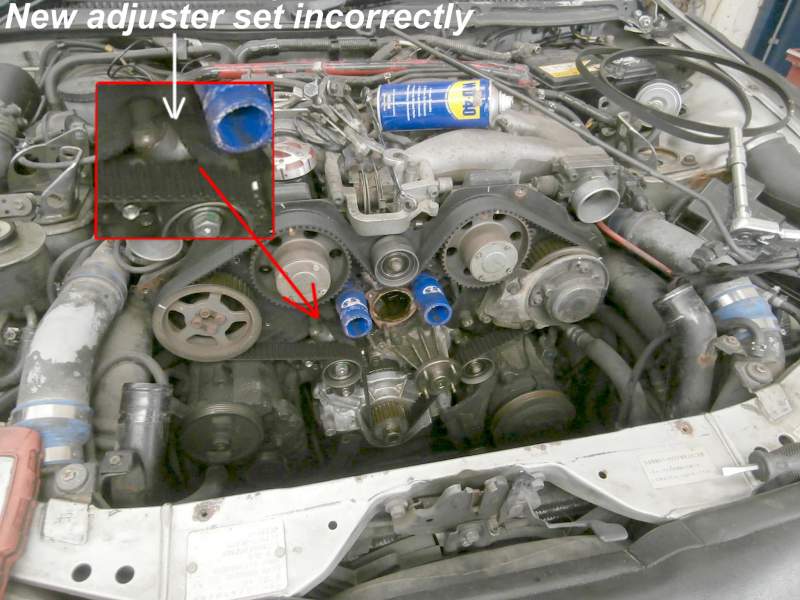

Whilst doing a cambelt yesterday I came across some poor previous work that should really not have been left as it was, the zed had been to another garage ( unknown non specialist) and had a fair bit of work including the cambelt and new pulleys and belt adjuster ( expensive). As you can see in the picture the adjuster piston is not in the set position and is totally closed, this effectively made it a manual non automatic adjuster, the cause of this is simple, the back plate of the adjuster has slotted fixing holes and is designed to allow you to dial in a set amount of pre-tension so the piston does not come out too far when a new belt is set. In this case the settings had been to harshly set and the piston had not even started to come out and the belt was way too tight, a simple slackening of the fixings and allowing the piston to come out 5 mm or so would have been a 10 second job. However as the pump had failed it all came off again and was replaced with a new belt even though the previous belt was only a couple of months old, but a new belt each time is a must do. The upshot of the adjuster been set incorrectly is a noisy belt in use ( no controlled slack) and a belt likely to last much less time / mileage than if set correctly, when making a quick acceleration move of the engine ( revving suddenly) you need a little bounce in the belt to stop it suffering from sudden whipping of the belt as the engine revs suddenly rise, not only that but after purchasing such an expensive parts for it to not be set correctly is a waste. With this all hidden once the job is done always use a garage happy to take pictures of the job and we have always done, its so much nicer that way to check how work has been completed. Jeff TT

-

300zx idle revving issues

You did not think I was going to sit on me harris in Portugal did ya?? Jeff TT

-

300zx idle revving issues

- 300zx idle revving issues

Lots of possibilities but as the op said its sometimes is ok it unlikely an air leak gets better and then worse at tick over speed. Jeff TT- 300zx idle revving issues

No it will not. Jeff- 300zx idle revving issues

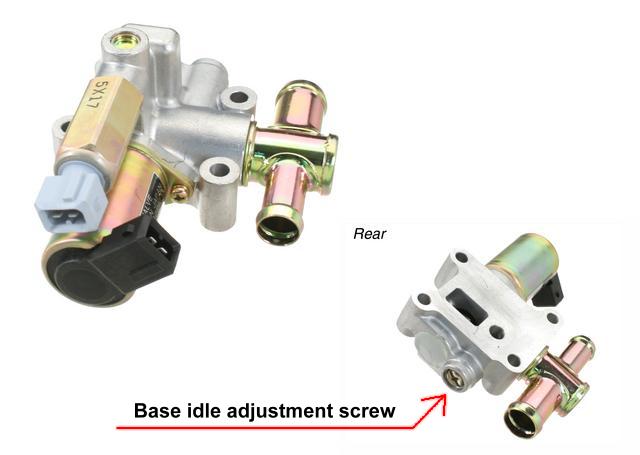

STOP!!! The issue you have is a simple one that has the potential to develop into more if you randomly or someone else randomly messes about with out knowing what your looking for. So the fault is a simple base idle tick over issue and a probable fault with the connection on the auxillary valve. The base idle is the mechanical setting that ensures that with no added tick over speed from the electronic idle stability solenoid that the engine cannot tickover less than 750 to 800 rpm depending on the setting which is done by adjusting the screw on the side of the valve ( back of the engine by the battery location) Locate the unit and identify the yellow connector on top of it, un-clip it and spray WD40 or similar into both the connector plug contacts and the unit contacts itself. Leave the plug undone and locate the adjustment screw ( sometime battery removal can aid this) spray WD40 or similar into the screw area and turn the screw in and out to free it up, now turn anti clock wise until the screw is level with the unit body. Reconnect the yellow plug and start the engine, hope fully with an improved connection on the unit the tick over will be stable now, and it also may be a little too fast, so when the engine is up to temp, remove the yellow plug again and slowly turn the adjusting screw back in ( clockwise until the tick over is set at around 800rpm, reconnect the yellow connector, do not worry if the revs rise they will stabilise after a moment. The idle control valve can play up even with a good connection so above is the first stage, if there is any more issues report back here. Hope that helps Jeff TT- Simple fuel gauge question

:blushing: Jeff TT- Simple fuel gauge question

The fuel gauge will be just fine Dave, it will just re set from the input from the sender unit as the stepper motor will have moved along with the needle it will just work out fine. Jeff- The phoenix will rise from the ashes

Just waiting for a return call from the recovery guys will update you asap. Jeff- The phoenix will rise from the ashes

The car is owned by my very best mate who I owe many favours to as he is a top guy so it was mates rates....if you get what I mean. Jeff TT- Alternator issue??

There is many issues that could be the cause of the running issues but doubt the alternator is the cause, try the in-build diagnostic check to see if there any fault codes. Jeff TT- The phoenix will rise from the ashes

- Conzult....

Buying a genuine ConZult is a great idea and not too costly, been able to read and understand what your seeing or in some cases not seeing is the tricky bit, most ConZult owners never get to explore the full potential of the kit and hence the full understanding of it. Jeff- is it possible in 10 days

Yes very possible, see it all the time on west coast customs, and the hot hot rod shop in the US, but then they do have the benefit of 20+ workers, pre-booked engine and trim work, lots of $$$$$ and of course a tv camera crew that can film the process in any order to make it work. Don`t do the repaint till you return ( will get chipped anyhow) and you have a chance Jeff TT- 1990 Tt auto boost issue

Safety boost as you say just lowers the boost not removes all boost, the easiest way to feel for the boost at the steel pipe is to place a rubber or latex glove over the pipe and it will either slowly inflate if the turbo is ok or will suck in slowly if the turbo. Jeff TT- 1990 Tt auto boost issue

Given the engine runs well as you describe there is little chance you have a boost leak large enough to have no boost at all. Almost certainly you have a seized turbo, and in 99% of the time it will be the passenger side turbo that fails in this way, any boost produced by the other turbo short circuits and is lost past the stalled turbo and down the exhaust. You can change the passenger side turbo with the engine in place quite easily so no engine removal required, check the failed turbo by removing the big throttle pipe and run the engine, feel for boost at the steel outlet coming from the intercooler ( not the throttle )been produced when revving the engine, try both sides and it will I am sure prove the n/s turbo is seized. Jeff TT- Little bit of help for tomorrow.....

Quite possible to disturb the injector connections when moving the balancer bar. Jeff. - 300zx idle revving issues