Everything posted by nickz32

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Finishing touches include laser etch EPR logo and warming, as well as it being clear coated to protect it from the elements

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

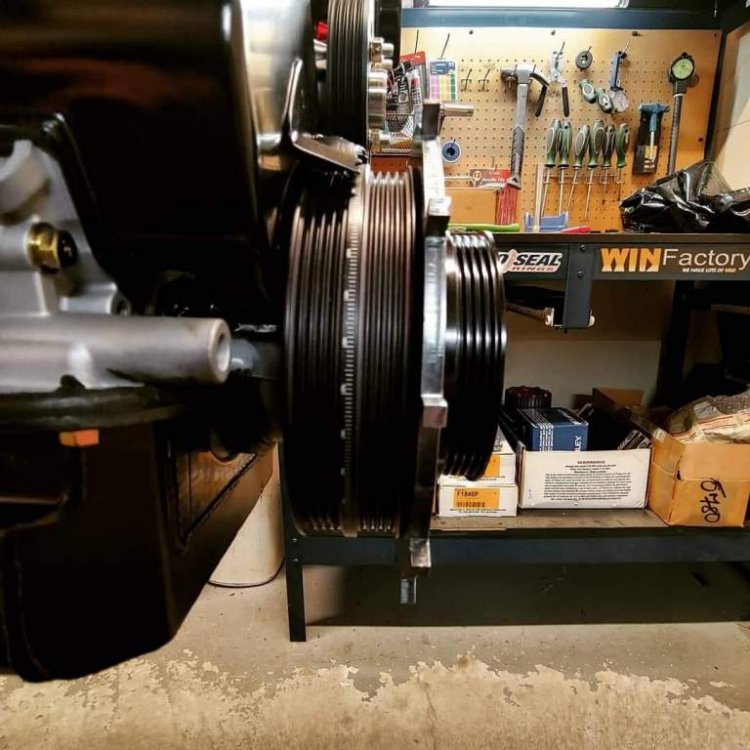

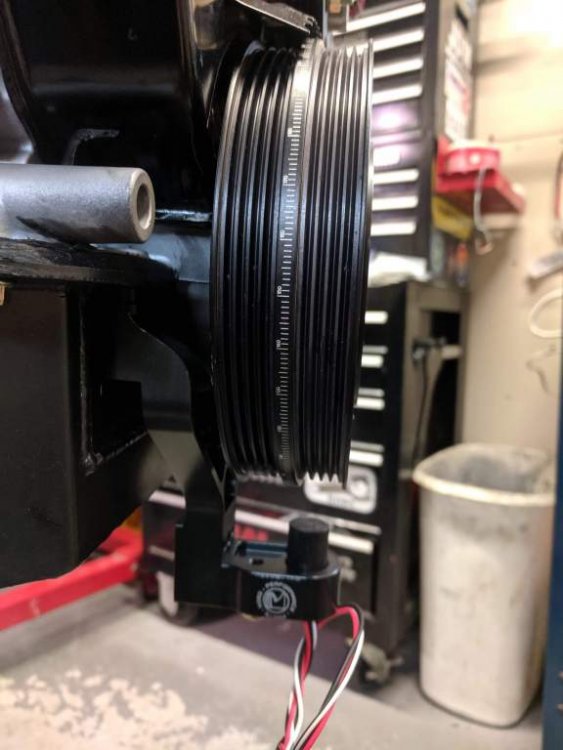

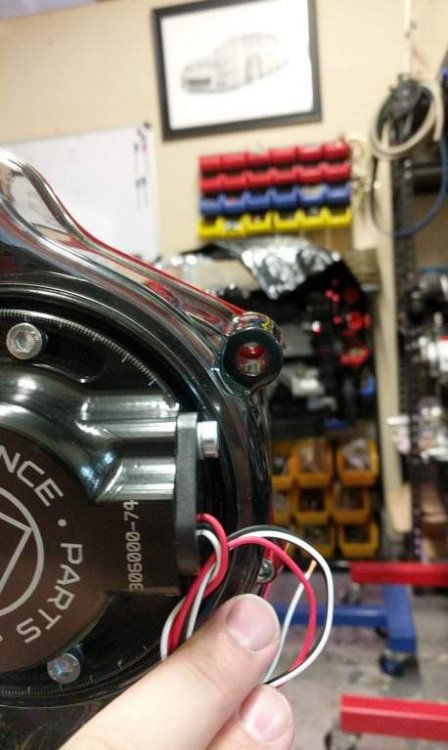

So the fundamentals of the trigger system are there The front pulley has been machined to remove material to ensure belt alignment for the PS pump is maintained. A Billet spacer is being made for the sensor mount to get everything lined up as it should be. All being well, the engine will be shipped at the end of this week!

-

crank pressure

Does it ever pop the dip stick after a spirited drive?

-

Lakes Weekend 2019 @ Fat Lamb 23rd to 26th August

Would have loved to have done this, but it’s fairly well documented why I couldn’t Personally, while I accept they were voted for, August Bank Holiday weekend would have more than likely ruled me out due to both work and family stuff. NC500 has been on my list for a while, as has visiting the Normandy Beaches. As long as their is some form of event like this next year, I’ll more than likely be there

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

This is the Hall effect sensor and mount that came with the Ross Performance kit. Obviously, it doesn’t have a ring to match up to and it’s in a different position to where the new ring will sit. The plan is for the new ring to sit at the front of the dampener behind the PS pulley and then spaced correctly to suit. The whole crank pulley will then be realigned to correct the offset with the PS pump [ATTACH=CONFIG]118170[/ATTACH]

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

This is the Hall effect sensor and mount that came with the Ross Performance kit. Obviously, it doesn’t have a ring to match up to and it’s in a different position to where the new ring will sit. The plan is for the new ring to sit at the front of the dampener behind the PS pulley and then spaced correctly to suit. The whole crank pulley will then be realigned to correct the offset with the PS pump

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

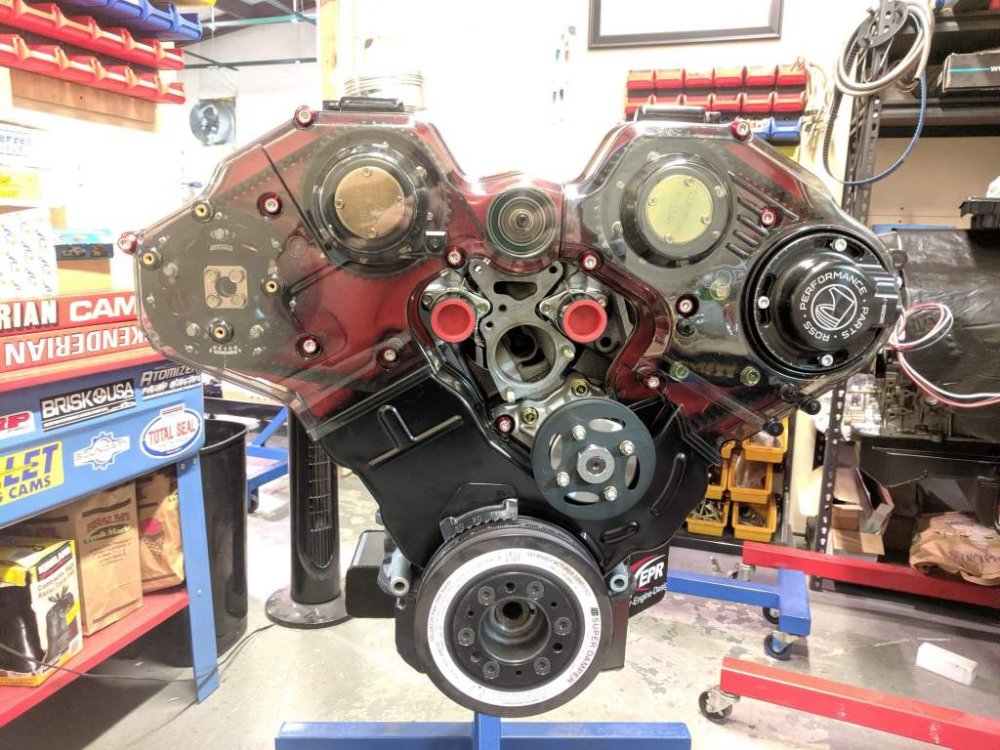

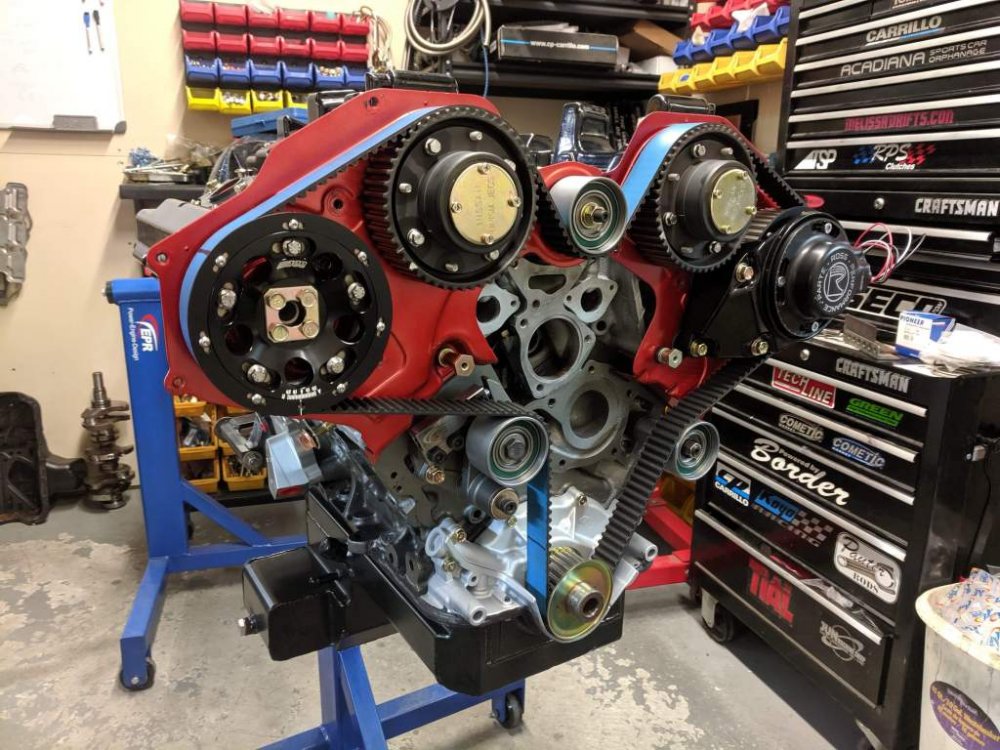

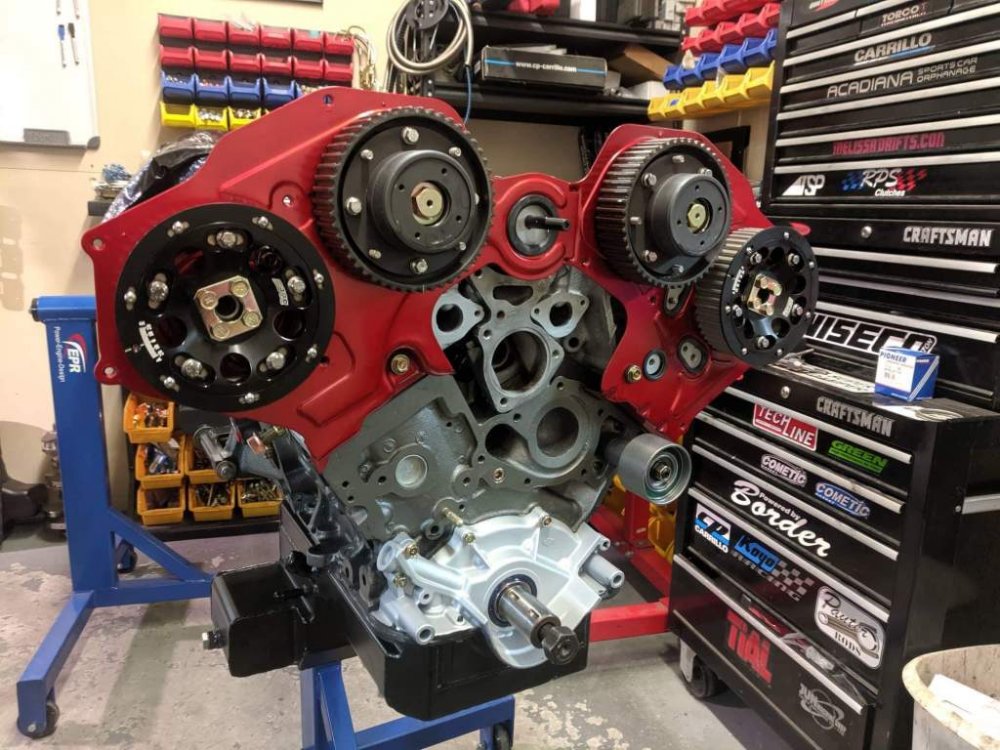

A well timed update to help make sure JaiKai doesn’t completely run away with the NEC voting poll :lol: Ain’t she a beaut! Annoyingly there’s a missing bolt in my Z spec kit! Hopefully Z1 can get one to Mitch sharpish Just waiting on the crank trigger wheel to be fabricated, hall sensor mounting, ceramic coating of hotside parts and I believe she’s done!

-

Display Car Vote : Classic Car Show : NEC 2019

Link to my project build thread: https://www.300zx.co.uk/forums/showthread.php?188495-My-daughter-calls-it-Toothless-the-Dragon-My-%9195-TT-Z Link to the dedicated Instagram account for my car: https://www.instagram.com/nightfury_z32/

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Just waiting on a couple of OEM parts to arrive at EPR (water pump and matrix pipes) so they can be fitted. I think Mitch still has to build the cradle for it to be shipped on. Hopefully it’ll be here in the next 2 weeks

-

Bluetooth playback ~ background speaker ‘schsissing’ noise

Does it only make the noise on Bluetooth connection, or does it do it if you connect via USB aswell?

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

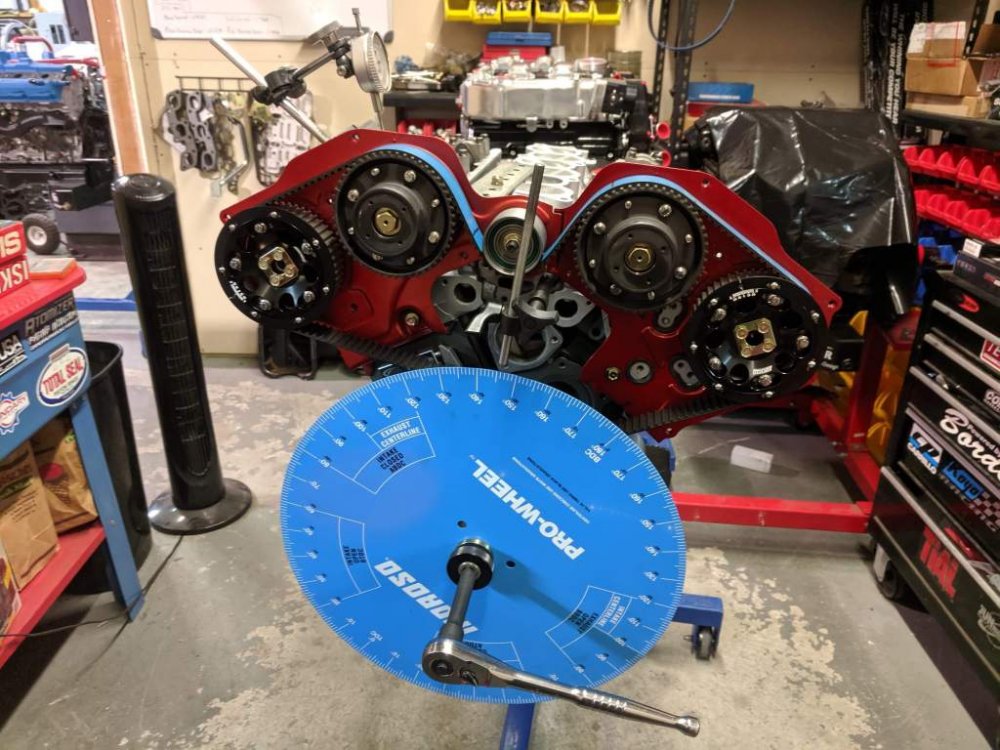

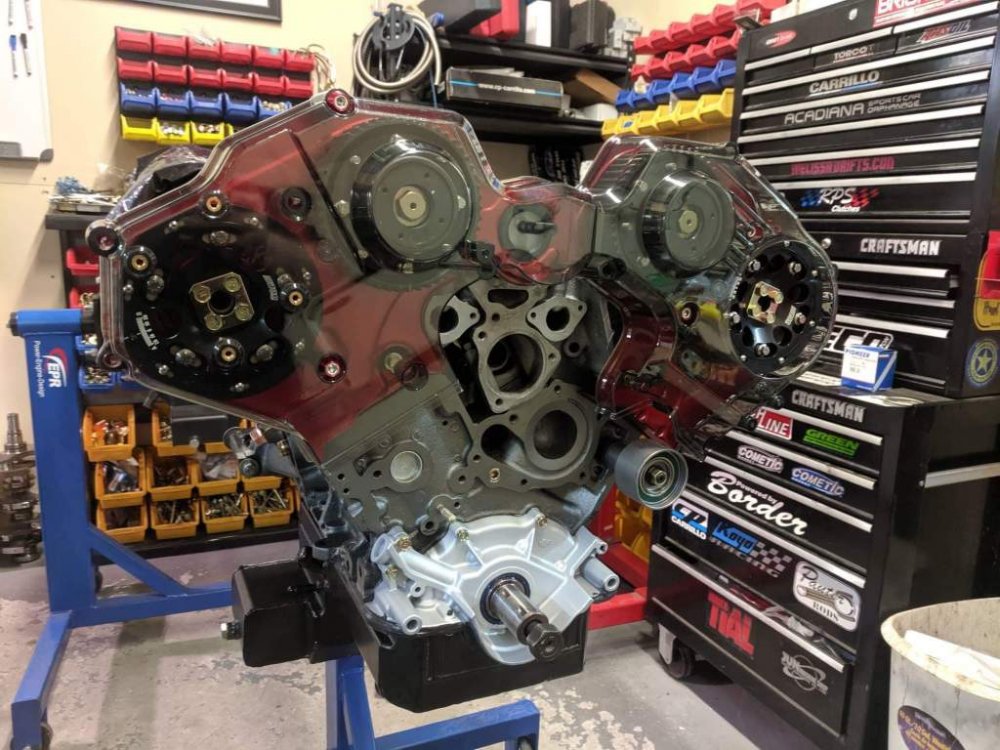

And here she sits, all timed up and ready to rock. Just a few bits to do, like set up the crank trigger bracket and wheel, aswell as the obvious timing covers, water pump etc

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

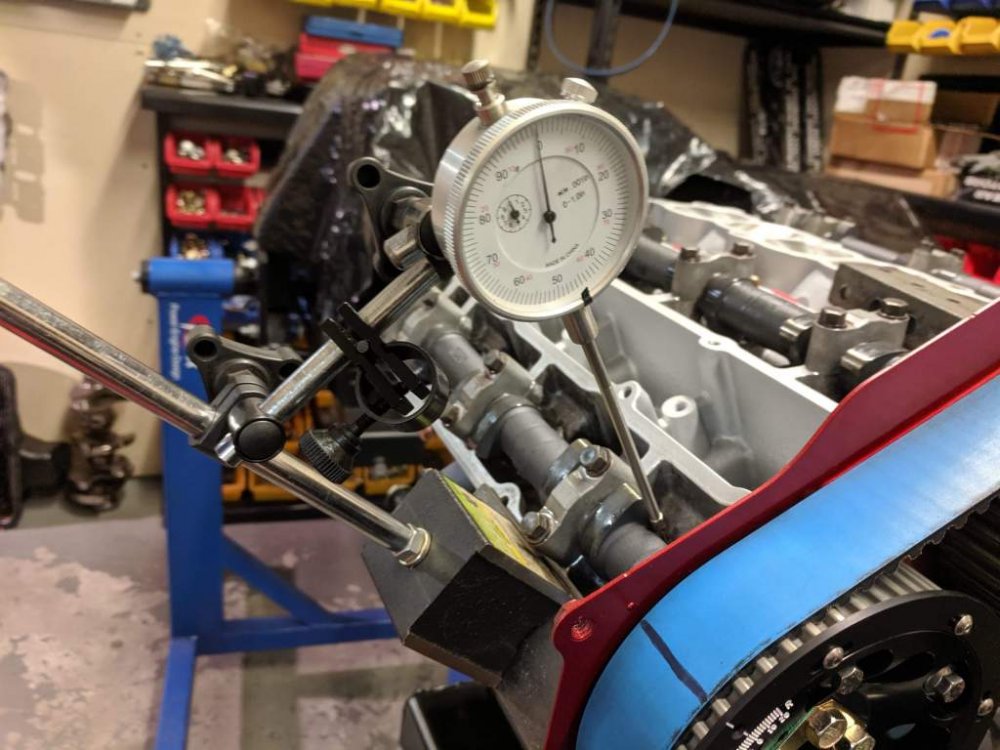

Getting closer. With the change of camshaft it’s paramount that they’re properly dialled in to ensure valve opening, closing and overlap happen when they’re supposed to. Furthermore, as my heads have clearly been skimmed, it’s equally important to make the appropriate adjustments are made to reset the centre line of the camshafts to crank. The adjustable cam pulleys make this possible and are a must when changing camshafts To make use of a large timing wheel (which makes the process easier and I’d guess more accurate) Mitch made up an adapter for the crank snout to enable the use of a bigger timing wheel Then the process began Hopefully this will be topped and tailed later today and the final bits and bobs will be installed ready for shipping

-

Max speed tests

Not used Elvington, but have done a Vmaxx event at Bruntingthorpe in the Z. Great surface there and used more regularly the Elvington so I think it’s better maintained

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

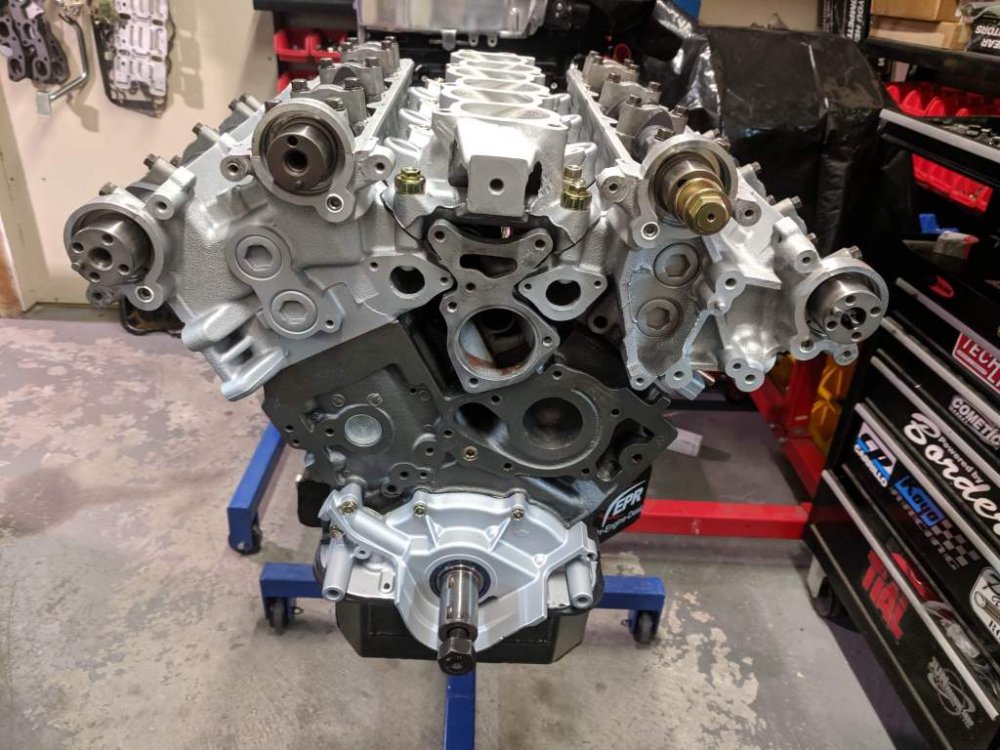

Plan is to get/keep the car to a similar standard to this engine..... it’s gunna be a long road but it’ll get there

-

Testing my patience...

Ah, forgot yours was a shortie

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

So after a chat with Mitch, a splash of colour has been added into the mix. Those of you who know me personally probably know I’m not a fan of multi coloured loud engine bays. Just not my style. However, I was stuck in a bit of a quandary. I’ve got nearly 1K’s worth of BDE cam gears that aren’t going to be visible due to the colour of the gears against the black backing plates. The colour scheme of my car has always been black with anodised red accents. So Mitch made a suggestion and after a bit of thinking I ran with it. Bold..... They’ve been painted anodised red, by coincidence, the same paint I used on my Plenum many moons ago. The idea was simple, to have a back drop that accentuates the black BDE gears Still too bold? Maybe..... but I’d always had in my mind I had smoked timing belt covers. And they’ve done exactly as I hoped With the anodized red fasteners, I think this is an in keeping way of highlighting the quality of the products used in this build (a bit like a window in a Swiss watch) without being overly shouty and in line with the rest of the car. Another nice little touch is these Copper exhaust nuts to prevent seizing in the future

-

Testing my patience...

Looks like windscreen washer bottle leaking

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Also just thinking, my heads have been skimmed 3 times, which is probably the biggest reason for the slight step ***edit, should read the replies first, what he said ^^^^***

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Thanks fella

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Yep

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Lower Plenum is now complete. EPR noticed that the Plenum was warped by 7 thou, so it’s been surfaced to correct. I also had a couple of iffy threads for where the upper Plenum bolts down to it. This has been resolved and all the threads have been replaced with Keen-Serts Unfortunately, it appears that the stock gaskets appear thicker than previously experienced. This has caused the lower Plenum to sit a little higher than the port by a smidge. A shame, but budget doesn’t allow for rectifying at the moment

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

Another little update. As the late series cars did away with the EGR system, it means the EGR valve mount on the back of the lower Plenum is redundant. So, to make getting to the knock sensor that little bit easier, it’s been machined off. Here’s a little sneak peak of the lower Plenum porting aswell

-

Z32 ABS braking system

I’d guess to accommodate an adjustable bias valve

-

My daughter calls it Toothless the Dragon: My ‘95 TT Z

OEM. They’re sprayed with a copper coating to help create a bond between deck surfaces.