Everything posted by redwine300

-

Radiator cross member replacement, day one.

-

Radiator cross member replacement, day one.

Well after a couple of more hours loosely fitting everything up, I finally managed to start welding. First 3 seemed to go okay, if not slightly off center.

-

Radiator cross member replacement, day one.

-

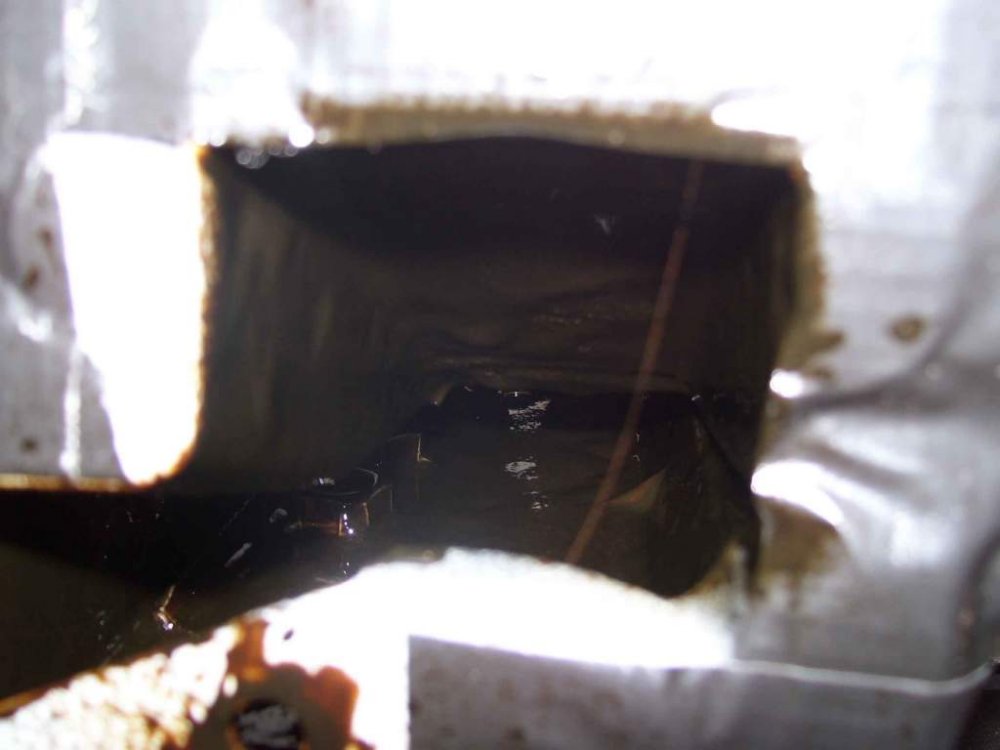

Return of the tin worm.........

Hi Russ, feel your pain mate. You could remove the two bolts that retain the sub-frame and and insert your lance there. That way you will directly next to the area in question.

-

Radiator cross member replacement, day one.

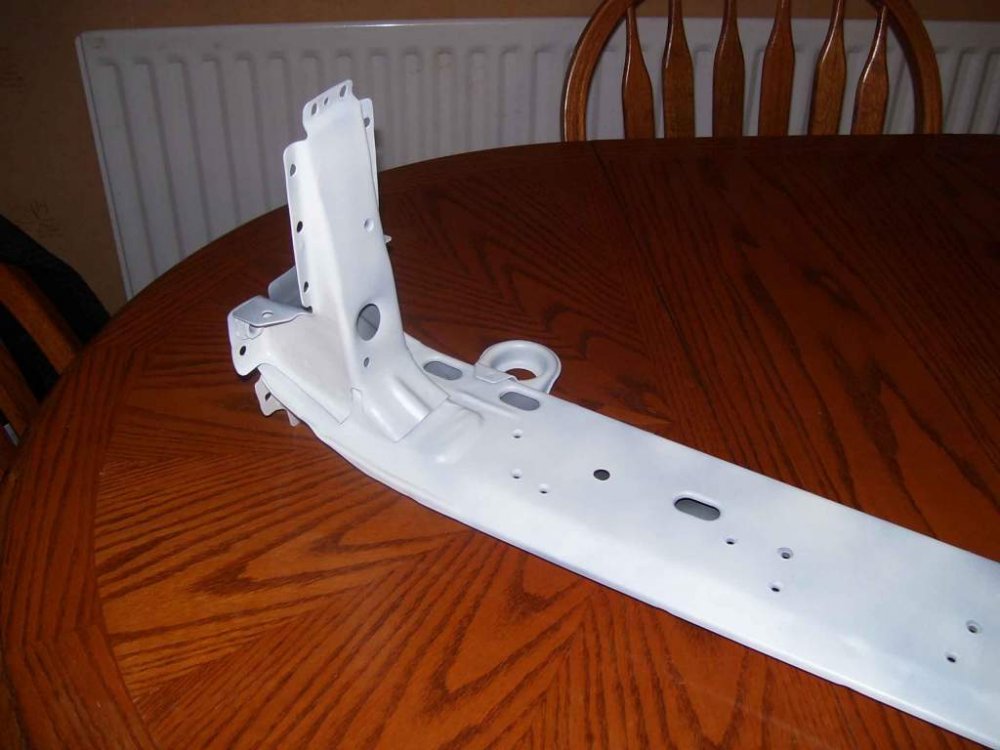

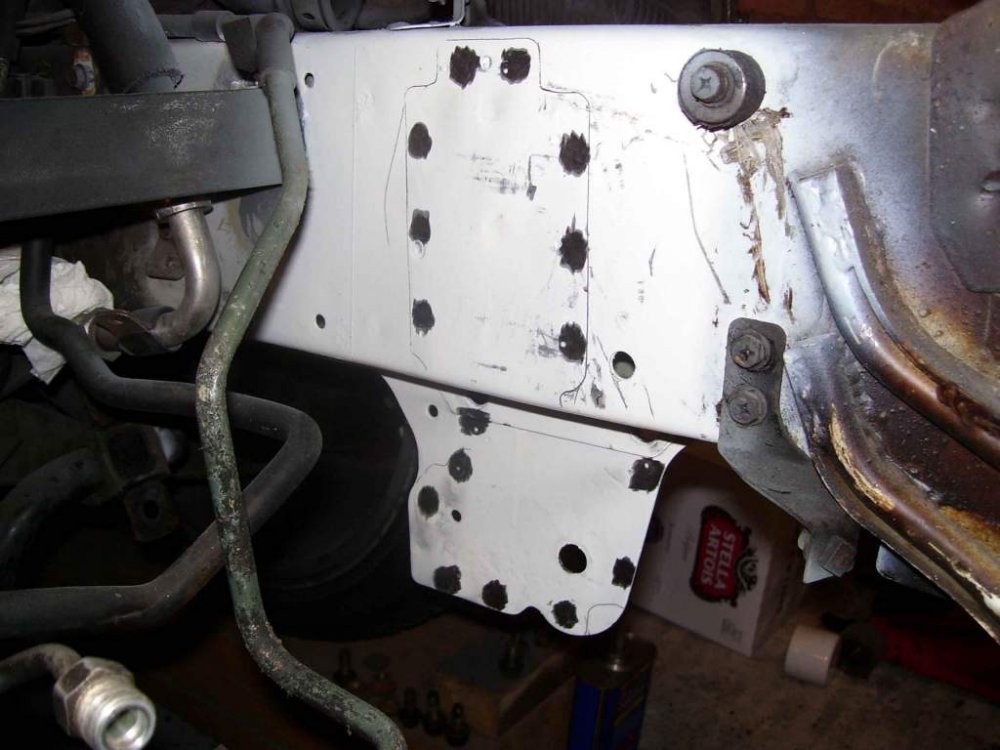

I agree znut, :thumbup1: I guess I was just doing as much up front as possible in the hope of a replacement, but I think I will have to go with this one. I will heed your advice and clean away the paint locally on each weld point before I start welding. I know I will make a mess of the paint locally, but I am prepared for a tad of dressing and touching up post welding. Just did not fancy finish spraying the whole thing in situ either, not with my history of overspray. :blushing:

-

Radiator cross member replacement, day one.

Just finished my first final fit before prep and weld and noticed that the left hand side remained vertical, but the right hand side is slightly distorted. Can not see how to correct it..

-

Radiator cross member replacement, day one.

:lol:

-

Radiator cross member replacement, day one.

-

Radiator cross member replacement, day one.

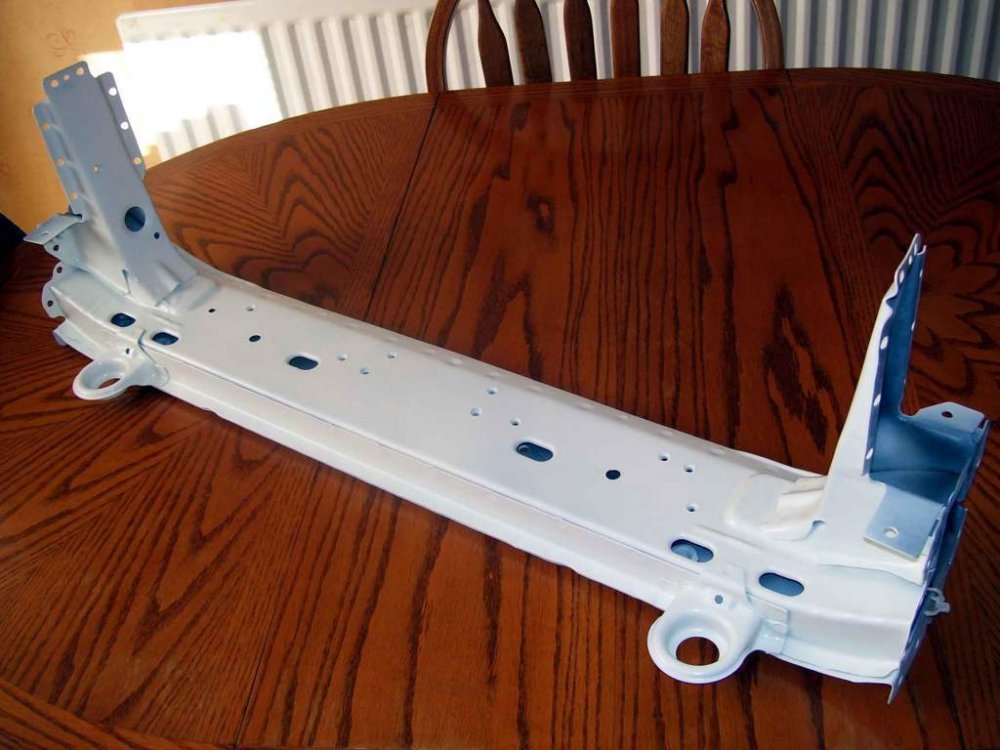

I know, I know, it's not welding, but you have to admit, putting the first layer of paint on is pretty cool. :yawn:

-

Radiator cross member replacement, day one.

Thanks Si, appreciated. :thumbup1:

-

Radiator cross member replacement, day one.

Thanks for the reassurance znut.. :thumbup1: Yes, I drilled out from one side of the spot welds and re-welded.

-

Radiator cross member replacement, day one.

Decided to finish off the repair as I have almost given up on a replacement. Just hope that my welds are strong enough.

-

What did you do to your zed today?

Nice work Russ, very impressive.

-

Radiator cross member replacement, day one.

Cheers znut, I think I will run some more trials along the lines of 678 as you suggest. Thanks. :thumbup1::thumbup1:

-

Radiator cross member replacement, day one.

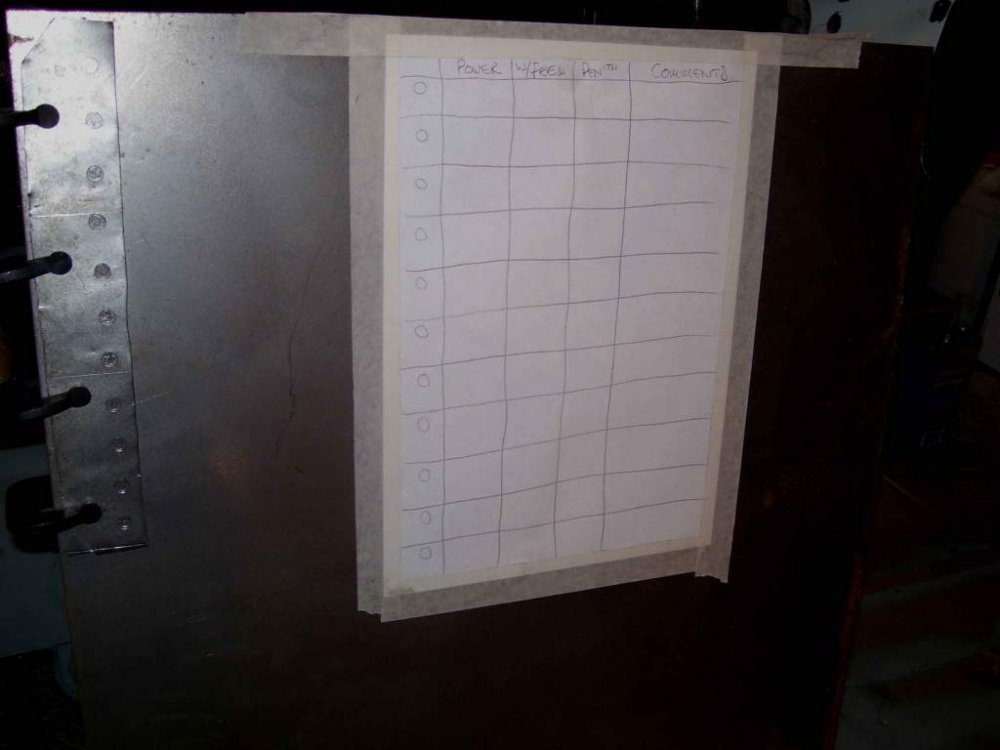

Ran my set up welds tonight, my god I am out of practice. Anyway, I decided to start at the lower end of my mig and work up monitoring the weld height and penetration as I went. Here's the results, no laughing please..... Starting from left to right.... (Clarke 135te turbo machine) First, power at 1 min, wire feed at 5. (poor penetration and spitting/burning back) Second, power at 1 min, wire feed at 5.5 (as above) Third, power at 1 min, wire feed at 6 (as above) Fourth, power at 2 min, wire feed at 6 (as above) Fifth, power at 1 max, wire feed at 6.5 (as above but with buzzing) Sixth, power at 1 max, wire feed at 7.5 (better penetration, some spitting) Seventh, power at 1 max, wire feed at 8 (better penetration, less spitting) eighth, power at 2 max, wire feed at 8.5 (fair penetration, some buzzing) ninth, power at 2 max, wire feed at 8 (as above, probably should have tried a wire speed of 9) tenth, power at 1 max, wire feed at 8 (good penetration, some crackle and some spitting) eleventh, (as above) If the welders amongst you would cast your eye over these and make suggestions as to how to improve things, I would be greatful.

-

Radiator cross member replacement, day one.

Ironic in deed, just can't believe the new one was faulty. As you say, I too have my doubts about a positive outcome, I can only hope that they have some integrity. Hope to have an answer by end of play today, one way or another. Naively, I did tell them about my tight time frame, maybe they will just wait me out and force me into fitting the one I have here.

-

Radiator cross member replacement, day one.

Don't get too excited, but I will be welding tomorrow. Only my set-up piece mind, just want to be deadly sure of my setting before I make a start in earnest. Be patient guys, it'll be worth the wait I promise. I will have to stop procrastinating sooner or later.

-

Radiator cross member replacement, day one.

Love it Russ.. :lol::lol:

-

Radiator cross member replacement, day one.

Not a lot to write home about I'm afraid, just some spot weld preparation whilst I await news from the Vendor. I have stated that as a bare minimum, I would expect a full refund, at best a good replacement. No news as yet though.

-

Electric Fan or Viscous? Also Broken Rad, Tech Info Needed

As I understand it, the rads are different and not interchangeable, but I am not 100% As for the viscous coupling? I would always go with it, so long as it is working correctly as opposed to an electric unit. As for a fix? they are prone to the small shaft sticking due to corrosion etc'. I would try a little WD40 sprayed into the shaft to see if it free's it up. If you do try and free it by hand, be very careful as the vane valve is very delicate, don't over rotate it.

-

Radiator cross member replacement, day one.

I understand your frustration mate, I am so close it is untrue. I think it is the uncertainty of whether I will secure a replacement or not that's holding me back. That said though, I have been prepping all of the spot welds by way of grinding back to bare metal in readiness to fire up the mig. Hopefully soon. May do some practise welds tomorrow. Your are welcome to join me in a Stella by the way.

-

Radiator cross member replacement, day one.

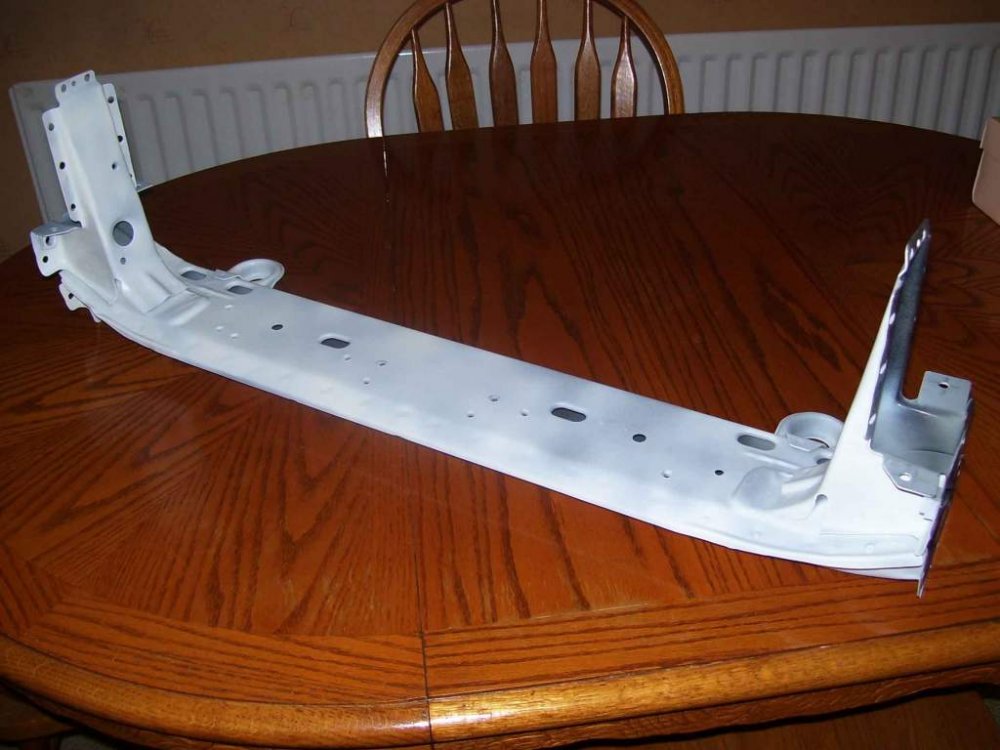

Well after a bit of fiddling, I managed to get the second side to line up as well as the first side. Not a lot of progress I know, just needed to feel happier about the alignment.

-

Radiator cross member replacement, day one.

: :lol::lol::lol:

-

Radiator cross member replacement, day one.

-

Radiator cross member replacement, day one.

Eureka! I have now managed to loosely fit the left and right hand tensioner brackets to the crossmember and chassis rail. Looks like I may have to position the crossmember a little better just to get both side as good as each other, but nothing serious. Can't thank you guys enough for the advice so far, (please keep posting) particularly Lymon and Slick Pete. :thumbup1: