Everything posted by scoobydoo67

-

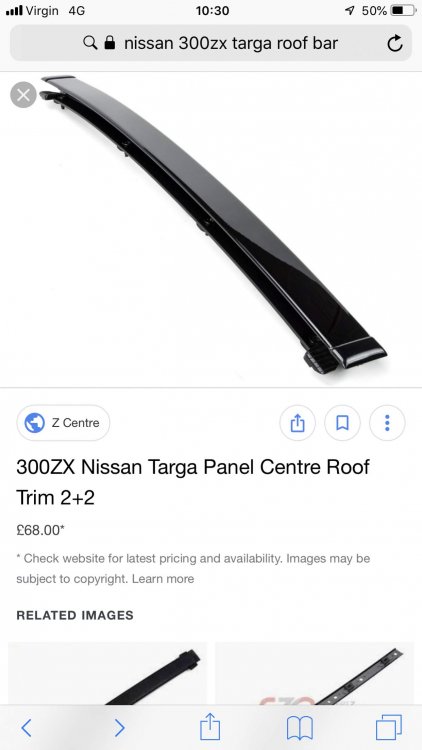

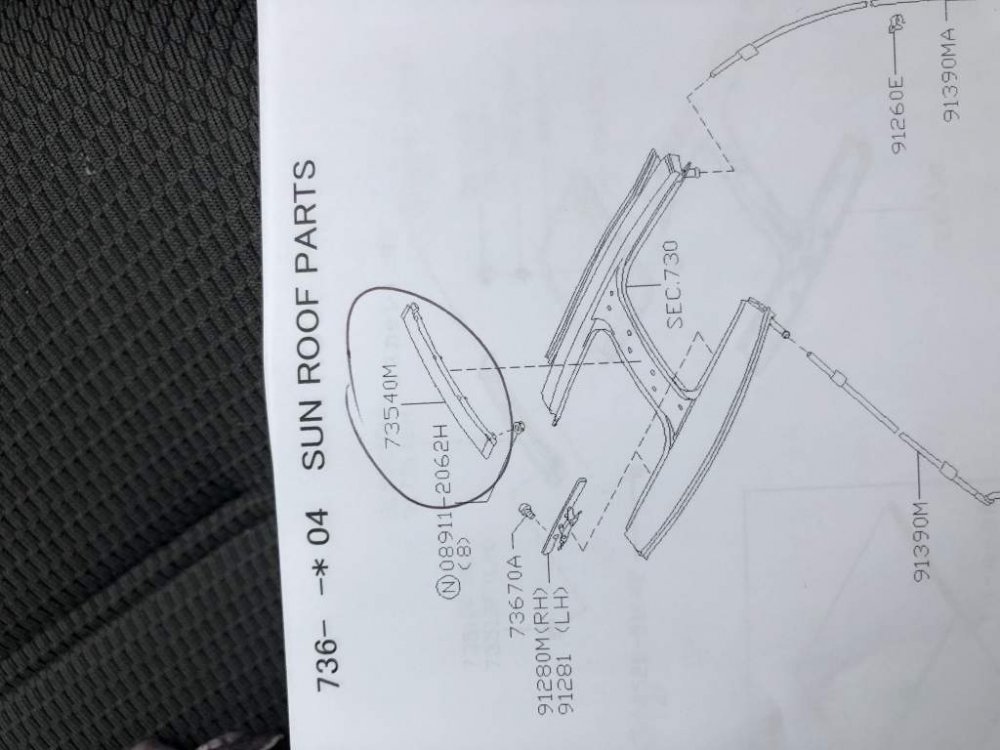

Targa roof bar plastic

Well I double checked with Nissan and they have ordered using the reg of car so should be the correct one fingers crossed

-

Auto to Manual conversion

-

Auto to Manual conversion

Do u mean the crank seal? I have the rear gearbox seal

-

Targa roof bar plastic

very nice and your car looking soo nice good work

-

Auto to Manual conversion

Just dropped off the flywheel to have the 0.011” 0.279mm step cut in left the old clutch and pressure plate with them to make sure they get it right hopefully. I will post pic when done and hopefully get a thumbs up from the experts on here. Thanks again Have also just picked up the pilot bush and rear gearbox seal

-

Targa roof bar plastic

Yep ordered

-

Targa roof bar plastic

-

Targa roof bar plastic

Hi gents Does any one know what the part number is of the the little piece of plastic that sits at the ends of the central bar between the targa panels? panels Thank you in advance ?

-

Auto to Manual conversion

Thanks for that Jimmer i will measure the clutch plate and the inside edge diameter of the pressure plate so i will know how much space i have between them and ask the company to re skim to suit. Will post more pics and info as the conversion goes on, I am sure more questions will arise so all you gurus please stand by :) Still need to get over and pick up that speed sensor Pete I will contact you this week to arrange.

-

Auto to Manual conversion

Thanks Andrew I am fitting a TT clutch and gear box into my na, so reading that having a flat flywheel on an na is ok but the TT requires that step. I believe it is all to do with the extra pressure from the pressure plate for the additional torque produced by the TT beast's. Would you happen to know what the diameter of the raised portion is? Or do i need to measure the new clutch plate and have it re cut to reflect that diameter? thanks

-

Auto to Manual conversion

In the service manual it just says about a run out of0.15mm nothing about a step. So bit confused now. Advice required please before I take it back to get it sorted out

-

Auto to Manual conversion

Ok looking at further pics online looks like there should be a step on the outer edge, so that the outer edge is thinner and then steps up to the friction plate surface. Does anyone know what the diameter of the friction plate surface should be and also what the depth of the step should be, have read values of 0.1” and 0.05”

-

Auto to Manual conversion

What sort of angle should it be machined at?

-

Auto to Manual conversion

Hi ya Jimmer how can you tell that? It was machine by a company who machine brakes and flywheels professionally.

-

Interior Group Buy - an update.

Well after nearly two and a half years the interior is out wrapped up and sent to Si on a pallet all ready for him to perform his magic. Good luck pal hope it goes well looking forward to the updates

-

Auto to Manual conversion

this is the box - - - Updated - - - also have had the flywheel re skimmed ready to fit for this conversion

-

Auto to Manual conversion

IMG_0791[12] this is the little box

-

Auto to Manual conversion

Any idea what the little box is next to the handbrake it has two braded wires in and a electrical connector the other end, unfortunately can’t load any pics

-

Auto dim rear view mirror

Hi looking at doing this as my interior is out and being re trimmed, the pics and share point don't work any more, can these be reloaded or has someone else got this information i can use? cheers S

-

What did you do to your zed today?

Well the time has come at last and the interior is now removed from the car and all wrapped up ready to go to Mondo for the full re trim including the roof lining and sun shades ( the last bit is news to Si hope he dosen’t mind haha whoops) Can’t wait to see it all done, it has been a long time coming but I know the end result will be worth it. With the interior being done I will hopefully doing sound proofing and swapping the auto for a manual. So going to be a busy few weeks.

-

Auto to Manual conversion

So got the gearbox today all looks ok, the flywheel needs a skim as it looks like the last use was doing burn outs and the face looks burnt. Haven’t got the manual wiring harness but I understand that a slight modification to the auto harness and all will be well. Haven’t been able to find much about what wires need to be remade to make it work, so if any of you have that information that would be good thanks. Or do I just buy a manual loom and if I did would I need one from an NA or From a TT? On the skimming of a flywheel is there any limits or thickness that need to be kept in mind?

-

Auto to Manual conversion

Cheers Chris will look into that any idea where the best place to get the pivot ball and clutch fork?

-

Auto to Manual conversion

Well a mate of mine is going to be picking up this gearbox set up for me on Thursday, so really looking forward to having a manual. Apparently the box is from a TT but is coming out of an N/A so it all should just bolt straight back in place including the prop shaft which is awesome. It will also come with a brand new clutch, which was a concern whether or not to buy a new one or fit the old one. Is there anything else i will need new ? And does anyone have the wiring diagram for the auto box and knowledge of what wires i need to connect/ splice or leave alone so that the car isn't looking for the auto to be in park etc? And poss a list of everything I might need just to be on the safe side? thanks

-

Auto to Manual conversion

That's awesome thanks In Chew Magna first thing but can swing by Bath anytime just give me a pm with yr number and address and I will call and arrange with you Stuart

-

Auto to Manual conversion

Thanks guys keep the info coming will need all the help. Does the TT have this extra reservoir? I could ask the seller to include it. Will see if I can find a NA speed sensor unless someone on here has one? Does anyone have the wiring diagram for the water loom? Spoke with Mondo earlier and he said that it is just 3 wires that need to be connected but he couldn’t remember which ones or if he still had the diagram