- Replies 421

- Views 34.4k

- Created

- Last Reply

Top Posters In This Topic

-

Stephen 224 posts

-

AndrewG 26 posts

-

Slick Pete. 23 posts

-

Joely P 23 posts

Most Popular Posts

-

After a bit of faff about with the battery which was a Covid victim we got to the MOT station. Happy to report a pass. The guy was pretty intense on it and I picked up some minors. He was fair th

-

So after a very long, dry, safe and cosy sleep since the beginning of this global pandemic she’s waiting for an MOT.

-

Just to update this. Ive now mot’d the 32. I’ve been and looked at a couple of Z34s and driven one this week which had a remap and an exhaust. About 30k on the clocks and clean. I was quite

.thumb.jpg.2e1577d00bb02236df046d693ff10b7c.jpg)

Right, thought I'd start this. As some of you may know my cars a bit broken at present and I have a pile of parts ready to fit that gets bigger without it making its way to the car.

So lets start with what's up with the engine. Myself and gaz pulled the engine about two winters ago now, as one of the turbo's had failed. Compression was tested at this time with a very even 170psi across the board. Pulling it all apart we found a multitude of issues, egr hanging off causing an exhaust leak old sockets rolling about etc etc. We took that time to replace every damn crusty water and vac pipe and delete just about anything I considered a waste of space.

Water plenum bypass,

EGR,

AIV,

PRV,

Cruise control,

Aircon,

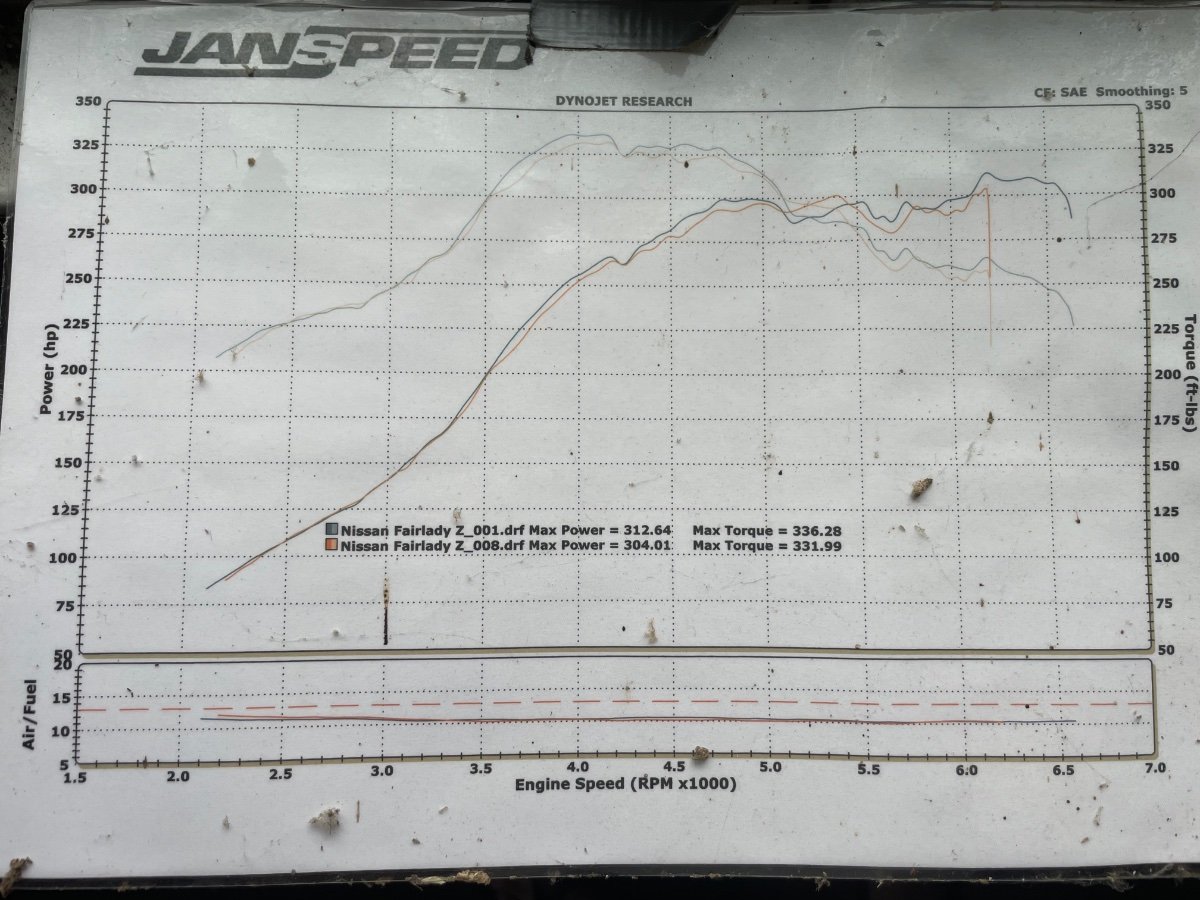

Think that's all. The turbos were rebuild by myself and for the first 50-100 miles things were bob on and I didn't give it too much stick. The first couple of pulls it detonated, new plugs, reduced the issue but it still did it a bit. Changed to a smaller gap and great the det was gone. The car was pulling very well at this point with virtually no lag and was dyno'd at 289hp bone stock, no extra boost no chip. Not bad for an old auto engine. Sadly it had started to smoke on over run, I assumed id cocked up one of the turbos during the rebuild. So I had been putting it off for months, well actually years now to pay out for brand new turbos. Anyways as the tax ran out I thought id do some more inspecting as the symptoms just didn't fit the pattern of failed turbos. The first thing I found was that lovely even compression was no more, cyl had a rather lame 115psi. Cue further inspection to work out exactly what block I had, manual/auto etc I assumed it was auto. That's when I found this...

That head casting reads R-10Y, wtf is that I thought. It's supposed to read 40P this was one of those penny drop moments. The piston crown sealed that moment of realisation and many dots connected.

That's right its an NA, 30p pistons are NA and 30p1 are TT defiantly no 1 on that code. Turns out r-10y is the later spec NA head aswell, so yeas 100% an NA block. Now this engine was fitted by a garage 4 years ago a few months into my ownership and we wont go into that too much but it wasn't a great experience and it transpires it was worse than I first thought. Anyway whilst they refused to reimburse me for that error, a good will gesture was sent out to me in the post of a few quid.

So a replacement engine is going to be sourced and fitted this winter. More of that and what's happening to the current late spec NA block.

So now more about that shelf of parts. I purchased last winter a full rear subframe assembly off Jaffa, the one off his time attack car. Loads of goodies already polybushed to death etc. So I stripped it down to bare metal and started painting it all with a few coats of lovely hammerite. This is how it stands at present;

So this winters aims are.

Remove front and rear bumpers, re underseal all of that and rip out and guff.

Delete HICAS system

Reloacte PS reservoir and fusebox

Switch over all suspension to new units from the shelf

Fit 354mm diameter brembos

Change engine out and preform various mods

It sounds like a lot, but hey winter is along time. Don't expect it to be coming through thick and fast. Im lazy haha